Battery Options

Here at Grin we've been dealing with ebike batteries for nearly 20 years during which we've offered over 100 variants of NiCad, NiMH, LiFePO4, LiPo, and Lithium-Ion packs in all kinds of voltages, geometries, and capacities. For many years batteries were one of the most unreliable and short lived parts of the ebike system, with packs getting worn out after just 2-3 years of use. But the rise of mass produced 18650 and 21700 cylindrical lithium cells for high power consumer goods like power tools has shifted the dynamic. Ebike batteries made with quality cells are cheaper, lighter, and with far longer life spans than we could have ever wished for in the past, and are also increadily dependable. We're happy to stock both frame mount and rear rack mounted batteries from 98 watt-hours to 1500 watt-hours in size to suit the needs of most electric bicycle conversions.

Battery Options

Grin's 2025 battery offerings include a mix of flat rack and downtube style batteries made with Panasonic, LG, and Samsung cells to suite a wide variety of user needs. In most models we use Anderson Powerpole connectors on the discharge lead, and ST3 port for charging at up to 8 amps, includes a robust BMS circuit for overcharge, over discharge, and overcurrent protection.

|

LiGo 10X 36V 2.75Ah |

Bottle Battery 36V 10Ah |

Reention 2170 DP4C 36V 14.5Ah |

Reention 2170 DP5C 36V 24.5Ah 48V 19Ah |

Reention DP9C 36V 26.5Ah

|

Triangle 52V 23Ah |

Canon-I 52V 29Ah |

eZee Flatpack 36V 14.5Ah |

|

|---|---|---|---|---|---|---|---|---|

| Energy | 99 Wh | 360 Wh | 520-680 Wh | 900 Wh | 1040 Wh | 1200 Wh | 1500 Wh | 720 Wh |

| Cells | LG MH1 | Samsung 35E | Samsung 50G | Samsung 50G | Panasonic GA / Samsung 35E |

Panasonic GA / Samsung 35E | Samsung 50G | LG MH1 |

| Max Current | 10 Amps | 25 Amps | 40 Amps | 40 Amps | 40 Amps | 40 Amps | 40 Amps | 35 Amps |

| Typ. Range | 8-12 km | 30-40 km | 50-70 km | 60-100 km | 70-115 km | 100-150 km | 100-150 km | 50-80 km |

| Installation | Varied | Downtube | Downtube | Downtube | Downtube | Downtube | Downtube | Rear Rack |

| Weight | 0.6 kg | 2.2/2.7 kg | 3.15 kg | 4.9 kg | 5.4 kg | 6.1 kg | 7.5 kg | 3.9 kg |

| UN38.3? | Yes | Yes | Yes | Yes | Yes | |||

| Charge Plug | XT60/ST3 | ST3 | ST3 | ST3 | ST3 | ST3 | ST3 | XLR |

|

LiGo 10X Battery

|

This is our smallest battery offering specifically aimed at people who want to travel or fly with their ebikes. Each LiGo 10X module is 36V 2.75Ah, so just under 100 watt-hours, exempting it from most of the class9 Dangerous Goods shipping restrications and even allowing transport in carry on baggage. You can parallel connect them for as much capacity as required, and series connect them for 72V setups. Designed and made in Canada by Grin Tech, it is the only battery we have now that is CUSMA compliant and can ship to the USA duty free. See the LiGo 10X Info page for more details. This is a new product from 2025 and replaces the first generation LiGo battery we produced from 2016-2022. |

|

Bottle Batteries

|

These cylindrical batteries mount in a cage that resembles a water bottle holder and are a great option when a smaller size pack is desired that is light and easy to carry. We carry both a short 36V 10Ah option, and a longer 48V 10Ah model. They are popular with folding bikes or minimal assist systems using small motors that don't draw much power. |

Reention Downtube Batteries |

Our broadest range of batteries are the downtube packs produced to our specification with the Poly DP enclosure series from Kunshan Reention. These are available in 36V, 48V, and 52V layouts and from 14.5Ah up to 24Ah in capacity. All the models we carry feature a motor controller mount in the battery cradle allowing for a tidey integration with our Baserunner motor controllers, making these the go-to battery choice for most of our kits. They are designed to bolt onto the water bottle eyelets of your frame tubing, though you can get a more secure and versatile attachment using our Triple Bob anchors. |

Triangle |

For even larger capacity needs we carry the triangular battery model which fills up the entire frame triangle of most diamond frame bikes. These enclosures have a set of velcro strap slots on all 3 slides to secure the pack in place, which does make it somewhat annoying to remove. |

Canon I |

And the largest battery option is the the Canon I "Gas Tank" battery pack, packing over 1.5 kWh in a single enclosure. This is a great option for people wanting a large battery in a downtube mountable casing reminiscent of a fuel tank, although the extra width can interfere with pedaling on some bike frames. We carry both a 52V 29Ah and 72V 19Ah model. |

eZee Flat Batteries |

Finally the eZee flat packs have a nice format for mounting on rear bicycle racks or around the platforms of cargo bikes where a lower profile is required. They featuring a locking on/off key switch and Grin makes a battery rail that can be bolted to an existing rack or other surface. These batteries use a 3 pin XLR charging port and are available in both 36V and 48V models. |

How to Choose a Pack

The very first consideration when choosing a battery pack is ensuring that it both fits your frame and can handle the current draw of your motor controller at the power levels you plan to run at. If you have a motor controller configured to draw 40A of current, but your battery is only rated to deliver 25A max, then either the BMS circuit will shut off the battery at full throttle, or the battery will be stressed and have reduced cycle life. The converse, having a battery that has a higher current rating than what your controller will draw is no problem at all.

The next consideration is ensuring that the battery is large enough for your required travel range; it's no fun having a battery go flat before the end of your trip. In order to determine the range that you will get from a given battery, you need to know both the watt-hour capacity of the battery, and how much energy you use per kilometer. Sounds complicated? Not really. As a rule of thumb, most people riding an ebike at average speeds consume about 10 Wh/km from their battery, and this makes the math very easy. If you have a 400 watt-hour battery, you can expect a range of 40km. A 720 watt-hour battery? ~72km

Of course, if you go really fast or are pulling an extra load, then this mileage will be worse, like 12-15 wh/km. On the other hand, if you use the motor more sparingly, then you can easily stretch it down to 6-8 wh/km. The table below summarizes the expected range for these different example batteries under light, average, and heavy usage paradigms:

| Range with Light Use | Range with Typical Use | Range with Heavy Use | |

| 3 Parallel LiGo (~300 Wh) |

35-45 km | 25-35 km | 18-22 km |

| 36V 14Ah Downtube (~500 Wh) |

60-80km | 45-55km | 30-35 km |

| eZee Flat Pack (~700 Wh) |

80-110km | 60-80km | 35-45 km |

| 52V 20Ah Downtube (~1050 Wh) |

120-150 km | 90-110 km | 65-75 km |

It makes very little difference whether you have a small geared motor, a large direct drive motor, or a mid-drive motor. The mileage and range figures for a given battery have to do with how you use the ebike, not which motor system is on the bike.

Tip: No one EVER regrets having too much battery capacity

The Case for Extra Capacity

Say you have a 12km trip to work and back, so to do the full 24km round trip you'll need 240 watt-hours. A 36V 8Ah battery at 288 watt-hours should be a perfect choice no?

The answer is that, unless you are seriously budget or weight constrained, this would probably be a bad battery investment. It might fit the bill initially for your commuting needs, but then it doesn't really leave any reserve if you need to run some errands on the way home or forget to charge it up one night etc. Even worse, small batteries will age more rapidly due to the higher average current draw per cell. At some point your 8Ah battery will drop to 7Ah, only barely enough for your daily commute and you'll have to bring the charger with you to work in order to ensure a return trip.

Most people find that once they have an ebike, they use it for all kinds of applications and trips outside of just commuting, and the ability to go 50+ km on a charge opens up possibilities that wouldn't have been possible otherwise. Plus, as the battery ages and declines in capacity, it still has more than enough range for your key commuting needs. Imagine if instead of getting an 8Ah pack, you purchased a 15Ah battery. Even if it loses 30% of its original capacity after many years of use, that's still over 10Ah more than adequate for the 24km commute.

Furthermore, if you have more capacity than required, then you also have the opportunity to do partial charging of the battery with a Satiator or similar device, so that instead of charging the pack to 100% to squeeze out every km, your standard charge is set to a lower 80 or 90% level. This can further increase both the cycle life and calendar life of a lithium battery by several fold.

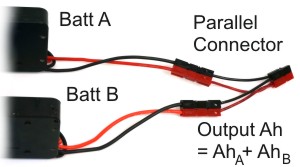

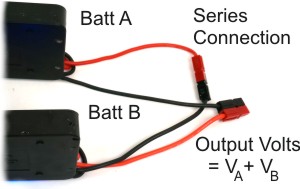

Parallel Connecting Batteries

One way to increase the current handling capability and range is to put two or more batteries in parallel. In general this is doable without too many issues. It is ok to mix old and new lithium batteries in parallel, or even batteries from different manufacturers and with different capacities, so long as they are the same voltage. We stock a parallel battery joining cable to facilitate connecting packs this way.

One way to increase the current handling capability and range is to put two or more batteries in parallel. In general this is doable without too many issues. It is ok to mix old and new lithium batteries in parallel, or even batteries from different manufacturers and with different capacities, so long as they are the same voltage. We stock a parallel battery joining cable to facilitate connecting packs this way.

Where things can get a bit dicey is in charging batteries that are parallel connected. If you leave the batteries in parallel while charging, then the charger current will get shared between the batteries and you can be sure that they are always at the same charge level. However, that does mean one of the batteries will be getting charged through the discharge port. For single port BMS circuits (like our LiGo 10X), this is not a concern, but on dual port BMS boards (separate charging and discharging mosfets) there is no overcharge protection on the pack being charged from the discharge leads. This can present a safety risk if there is a cell anomaly in that pack.

Alternately, you can separate the batteries and charge each with its own charger and then connect them in parallel just for discharging. Just make sure that both packs are indeed fully charged, as you don't want to connect them together when one pack is charged and the other is flat.

36V or 48V?

We sell roughly equal numbers of 36V and 48V battery packs, and all of our conversion kits and controllers work fine with both 36V and 48V (or 52V) battery options. The voltage will simply impact the maximum unloaded speed of the motor. Just because 48V is a larger number, it does not mean that a 48V ebike is intrinsically better / more powerful / faster than a 36V ebike despite what the ill-informed internet will lead you to believe. In an abstract level all that matters there is the total power (in watts) going into the motor, not the voltage at which that power is delivered.

However, it is true that a given motor winding will have the ability to spin faster at a higher voltage, and that leads to this perception of higher voltages being faster and more powerful. A fair apples to apples comparison requires changing both the battery voltage AND the motor winding. For instance, the slow wind Grin motor (7.5 rpm/V) at 48V is effectively identical to the standard wind motor (10 rpm/V) at 36V.

For most of the hub motor kits that we offer using the recommended motor winding for the wheel size (ie fast wind in 20", slower wind for 26"), a 36V battery will result in a full throttle commuting speed of 30-35 kph, while wth a 48V battery will result in closer to 40-45 kph. But you can choose other voltage and winding speed combinations depending on your need.

If you are upgrading or replacing an existing battery pack, it is always safe to replace it with a battery that has the same nominal voltage. If you have a generic 36V ebike setup that is not from us, and are looking to 'upgrade' to a 48V/52V pack for a higher wheel speed, more often than not you can do this without damaging the existing electronics. That is because most 36V motor controllers use 60V rated mosfets and 63V rated capacitors, and so even a fully charged 52V battery will likely not exceed these values. But it might.

Series Connecting for 72V?

It is also possible in principle to series connect two 36V batteries to make a 72V setup, but the only battery we have that is intrinsically designed for this is our LiGo modules. With all other batteries, it is essential to use a pass diode across the output of each battery so that when one BMS circuit trips it does not get exposed to a large negative voltage. We have a special series battery cable with this diode built in available here.

When you series connect batteries, you want to make sure they are packs with identical capacities and specs. You also want to make sure that either your controller or Cycle Analyst low voltage cutoff is set such that the discharge stops as soon as one pack trips. Otherwise continuous current will continue to flow through the pass diode when you are running off just the one non-tripped battery, causing the diode to overheat and fail.

Battery Connectors

We like to use Anderson Powerpole connectors as the standard discharge plug on all of our ebike battery packs. These connectors are ingenious since they are genderless, allowing you to use the same plug both on both a load and a source, and the connector design allows them to withstand the arc of inrush current when plugged into capacitive loads much better than bullet style plugs. For the charging port, we like to use the female 3-pin XLR plug standard. This is directly compatible with the Satiator charger, and the quality Neutrik XLR plugs are rated for a full 15 amps per pin allowing very rapid charging. Unfortunately, this option is not available for many of the downtube battery enclosures. We originally used the very common but low current DC 5.5 x 2.1 mm barrel plug, but have since updated to using the 3 pin connector from ST which is safer, supports higher currents (8A is no problem) and has a 3rd pin for battery temperature sensing.

Battery Shipping

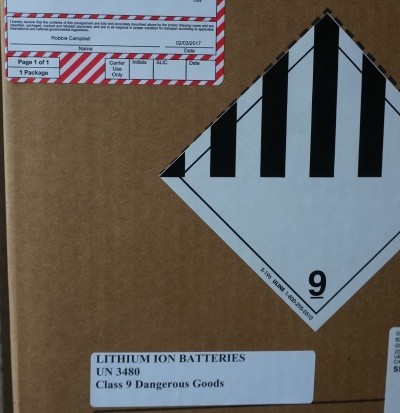

The shipping of lithium batteries is a complicated endeavor that frustrates the logistics of supplying and supporting ebike conversions kits. After numerous incidents of early lithium batteries either smoking or catching fire in transit, the transportation industry as whole recognized that lithium packs could not be handled casually like regular cargo and greatly stepped up the regulatory framework governing the shipping of lithium battery packs. Large ebike batteries are treated as Class 9 Dangerous Goods. In order to ship a large lithium battery (whether by ground or by air) very strict packaging and labeling requirements must be followed, the battery must generally have UN38.3 test certification, and the person doing the packing and shipping has to be trained and certified in the handling and shipping of dangerous goods.

The shipping of lithium batteries is a complicated endeavor that frustrates the logistics of supplying and supporting ebike conversions kits. After numerous incidents of early lithium batteries either smoking or catching fire in transit, the transportation industry as whole recognized that lithium packs could not be handled casually like regular cargo and greatly stepped up the regulatory framework governing the shipping of lithium battery packs. Large ebike batteries are treated as Class 9 Dangerous Goods. In order to ship a large lithium battery (whether by ground or by air) very strict packaging and labeling requirements must be followed, the battery must generally have UN38.3 test certification, and the person doing the packing and shipping has to be trained and certified in the handling and shipping of dangerous goods.

When you order a large battery from us, there is an automatic Dangerous Goods handling fee that is added to the order, and your battery pack is shipped separately from the rest of the kit as dangerous goods cargo. The exception is our LiGo 10X battery, which is separated into <100Wh modules prior to shipping allowing it to ship with your kit without extra fees.

Canadian

Canadian

Grin Tech Online Store

Grin Tech Online Store