Bike Compatibility

What Fits with Your Bike

The purpose document is to help people understand the compatibility and fitment issues with various bike frames and hub motor conversion kits. Most bicycles getting electrified have standard 100mm front or 135mm rear dropouts and not much consideration is required, but there are many more specialized bike frames that can be accomodated as well.

Know your Dropouts

First it is important to be familiarized with the term dropout. The dropout is piece of the bicycle frame or fork that holds the bicycle wheel to the bike. In traditional bikes, this has the form of an inverted 'U" shaped channel in a flat metal plate that is welded to the frame tubing.

Higher end bikes these days use thru-axle dropouts instead of slotted dropouts, where the axle fits through a hole in the frame instead of a slot. This provides better wheel stiffness and security (the wheel can't fall out even if the axle is loose), but has opened a can of worms for compatibility. Both the shape of the dropout slot itself and the spacing between the left and the right dropouts on the frame determine what hub motors will or won't be compatible, or what small modifications will be needed to make things fit.

The Classic Mountain Bike (100 /135)

The late 1980's to early 2000's saw almost all bikes using the same slotted dropout standard. The front fork dropouts were spaced 100mm apart, and the rear frame dropout was spaced at 135mm, giving sufficient room for the 7, 8, 9 and eventually 10 speed gear clusters on the back. The width of this dropout slot was ~9.7-10mm, so that the standard 3/8" bicycle axle would slide in with ease.

The late 1980's to early 2000's saw almost all bikes using the same slotted dropout standard. The front fork dropouts were spaced 100mm apart, and the rear frame dropout was spaced at 135mm, giving sufficient room for the 7, 8, 9 and eventually 10 speed gear clusters on the back. The width of this dropout slot was ~9.7-10mm, so that the standard 3/8" bicycle axle would slide in with ease.

This is also the standard that almost ALL ebike hub motors on the market are nominally designed to fit. If you have a classic bike like this then you have a huge selection of compatible front and rear hub motors. In some cases you may need to file open the dropout slot a little in order for the axle to slide in, and in other cases you may need so spread the rear frame a little to span more like 138-139mm, but for the most part you'll have very few fitment issues with hub motor electrification.

Folding Bikes (75/135 or 75/120)

Folding bicycles need to be compact, and as a result they often use narrower hubs and smaller dropout spacing than standard bikes. It's very common for the front fork of a folding bike to be 75mm apart instead of 100mm, and for this we supply special narrow folding bike motors.

Most folding bikes that have a full set of derailleur gears will still have a standard 130 or 135mm rear dropouts, in which case you have the option of any standard rear hub motor. But folding bike models with single speed gears on the back or with internal gear hubs are frequently a narrower 120mm standard which eliminates compatibility with standard rear hub motors.

Tandem Bikes (100/145)

Many tandem bicycles use a wider dropout on the back in order to have a stronger rear wheel due to the extra mass present on tandem bikes and the tendency of heavily dished rear wheels to buckle. Because most hub motors are actually more like 138-139mm wide, it's usually easy enough to make this work by installing a few washers on the axle to space it out and a corresponding spacer on the disk rotor as well. Grin's Rear All-Axle motor includes adapter sets for 145mm tandem bike dropouts, and even the extra wide 160mm Santana Tandem bike frames.

The front forks on tandem bikes use standard 100mm spacing and before our rear All-Axle motor we'd often suggest a front kit. On a tandem bike, the weight is evenly split between the front and rear wheels so concerns about traction with front wheel drive are not well founded.

Fat Bikes (135,150)/(155-190)

Fat tire bikes have experienced a range of frame geometries as the industry kept experimenting and getting fatter. Initially fatbikes used a front fork with a 135mm dropout spacing and a rear hub that was 150-165mm, sometimes with an offset frame to prevent chain rub on the tire. Fat frames using a 135mm front fork allow the use of a standard rear hub motor to fit on the front wheel instead. The ~150mm rear spacing could be accommodated by most rear motors using some spacers on the axle.

At present, most fatbike frames use either a 170-175mm or 190-195mm rear dropout slotted dropouts, or 177mm / 197mm thru-axle dropouts. Grin's Max45 all-axle hub motor series comes with adapters that work for all these dropout options and is our recommended option. There are also many generic geared motors similar to the Bafang G60 or G62 hub sized available for slotted dropouts. The front forks often use a 150x15mm thru axle hub and there are adapters available for both our regular (27mm stator) front All-Axle hub and the more powerful Max45 front hubs.

When lacing a hub motor in a fat tire rim it is important that the left and right rim holes are closer together than the motor flanges so that the spokes are triangulated for dishing. Many fatbike rims have widely separate left and right spoke holes are not compatible with hub motor builds. We stock a DHL65 rim which has close to centerline drilling that works very well in most cases.

IGH Bikes

Bikes with an internal gear hub usually have horiztonal dropout slots to allow the rear wheel to slide back and forth for chain tension. It is no problem installing a hub motor in horizontal dropouts, but if the frame lacks a derailleur hangar then you won't be able to use the gearing. If you are electrifying a bike with an internal gear hub we generally recommend using a front hub motor. But if it suits your needs we also carry a TDCM IGH rear hub which has a 5 speed sturney archer hub inside a direct drive hub motor.

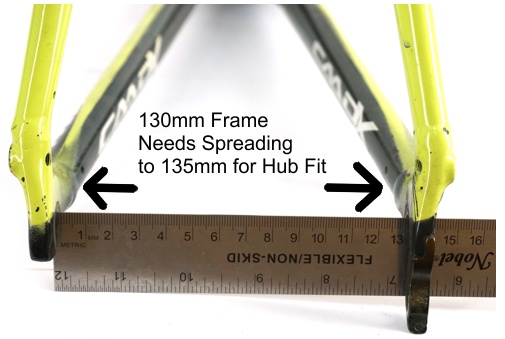

Road Bikes (100/130)

Most old road bikes have a 100mm front fork spacing and a slightly narrower 130mm rear. They will fit standard front and rear hub motors, though the rear motor option requires a bit more frame spreading than on a mountain bike. Lightweight road frames are generally best electrified with small lightweight geared motors to maintain the nimble handling of a road bike.

These installations can get a bit more complicated around the drop bar handlebars. It is not very easy to fit a normal throttle or ebrake lever on a drop-bar with bar-end shifters installed. Our usual solution involves the handlebob post to provide a mount for thumb throttles and auxiliary adjustment devices.

Thru-Axle Bikes

Thru-axle frames used to be just the domain of very high end downhill mountain bikes, but are now found across the board even in commuter bikes and road bikes. As usual, the ebike industry has been slow to keep up with the bike industry, and as usual at Grin we've been at the forefront of fixing that.

The Grin All-Axle motor was designed from the ground up to to support both front and rear thru-axle systems in all their variants and is the only hub motor on the market doing so. For front hubs, that includes, 12, 15, and 20mm thru-axle axles, in both regular (100mm) and boost (110) lengths. It also includes 150x15 thru-axles on fatbike forks. For rear hubs, it supports the original 142x12, plus the 148x12 boost size, and the 157x12 superboost, along with Santana's 167x12 Tandem Bike thru-axle.

Tadpole Trikes

Tadpole tricycles have two front wheels and one rear wheel, and usually feature a reclining seat position. The most common electrification is with a single rear hub motor which works well on setups that have derailleur gears. It's also possible to electrify the front wheels of many tadpole trikes using our All Axle hub motor and an appropriate single side adapter.

This front motor install has the benefit of leaving the drivetrain alone (and allowing the use of Rohloff and other IGH's) and it provides an option for 2WD front motor setups for extreme power and performance. A single All Axle hub on just one side will provide enough power for most users and contrary to expectations it does not produce any noticeable handling asymmetry.

Delta Trikes

Delta trikes have one front wheel and two rear wheel,s with the rider typically in an upright position. They commonly have a basket or a larger cargo hold in the back with the pedals driving a shaft that turns the right rear wheel while the left rear wheel freewheels. On these trikes a torqey front hub motor usually works just fine. For cargo applications that require higher levels of assist, is it sometimes possible to do a dual motor setup with an All Axle hub motor on one of the rear wheels.

Dutch Cargo Bikes

Most imported dutch cargo bikes have an internal gear hub on the back and use drum brakes rather than disk or rim brakes, so the frames lack both dereailleur hangars and the mounts for mechanical brakes. As a result a hub motor installation removes one of the brakes, and it leaves the TDCM IGH rear hub as the only compatible rear motor.

If you already have one of these bikes then the best solution is to locate a metal shop that can cut and weld on a disk caliper tab to the forks so that it becomes properly disk compatible. If this is not available, then there are also some aftermarket disk brake add-on devices though they look a little hokey. If you are a shopping for a new cargo bike we highly recommend sourcing a model that uses disk brakes and derailleur to have the best motor compatibility.

Belt Drive Bikes

Systems with a belt drive and internal gear hub should simply use a front hub motor. If you have a system that uses a belt drive with a pinion gear in the bottom bracket, then you have the option of our single speed Max45 motor with a gates cog.

Freewheel vs Cassette Freehub

Most people respond with a blank stare when we ask if their bike uses a screw-on freewheel or a cassette freehub system, which is understandable since externally they both look like a cluster of gears. Sheldon Brown has a good summary of the differences.

The threaded freewheel assembly is the original standard for rear 5, 6, and 7 speed gear clusters. In this design, the hub has a 1.375" x 24tpi threaded boss on it and the entire cog set and freewheel screws on the hub as one piece. In a cassette freehub system, the freewheeling mechanism is part of the hub, and instead the cassette cluster contains just the gears that slide over a splined interface. The cassette freehub system would be found on almost all bikes with 8 or more speeds.

Why it matters?

Up until recently almost all rear hub motors used the old screw-on freewheel standard and not the newer cassette freehub. As a result people doing electric conversions would frequently need to downgrade their 8-9-10 speed shifter/derailleur system to a 7 speed setup. Seeing an opportunity, the companies in the once declining freewheel business started to offer higher speed freewheel options that never used to exist in this standard. First 8 speed, and then even 9 and 10 speeds, so that threaded freewheel hub motors could be used with more modern drivetrains. Unfortunately the quality and variety of these 9 and 10 speed freewheels is nowhere near the same as what is available from companies who produce cassettes for splined freehubs, and the tolerances required for reliable indexed shifting is very tight with the narrow cog spacing in these higher gears. Even though you may find a 9 or 10 speed screw-on freewheel, the cog spacing and shifting often is not as smooth as the original cassette cluster.

At this stage there are now many geared and direct drive rear hub motors that include a Shimano compatible splined freehub, which allows you to transfer over your existing cassette or source from wide range of industry standard cassette clusters.

What to use?

For bikes that have a 7 or 8 speed shifter the freewheel system is perfectly fine, but if you have a 9, 10, or 11 speed drivertrain and are looking to do a rear motor conversion, we would strongly recommend sourcing a hub motor that has a cassette freehub. If you do end up using a motor with a threaded freewheel, then you might consider changing the gear system to use an 8 speed chain and shifter which are easier to setup.

It should be noted here that there is a slightly longer Shimano freehub standard for road bikes, and that SRAM has their own XD freehub body to allow smaller 10 tooth cogs. Almost all hub motors with cassettes use the most common original Shimano mountain bike freehub standard.

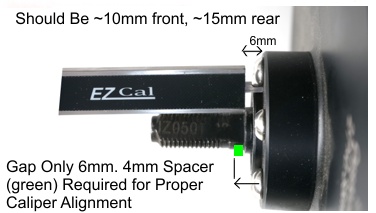

Disk Rotor Alignment

In standard bicycle hubs with disk brakes, the disk rotor flange is located ~10mm inside the left dropout on the front fork and ~15mm in the rear. The disk caliper has some room to move left and right to accommodate slight variation in the rotor position but if it varies too much then the pads of the disk caliper will always rub against the rotor.

Unfortunately many generic and even some brand name hub motors that include a 6 bolt mount for a disk rotor do not position the disk rotor properly to this standard. The disk sits several mm further to the left in order to leave more room for the hub motor itself. There are two options to have stop the caliper from rubbing badly in this situation.

One possibility is to adjust the caliper mount on the fork to move it further to the left, either by elongating the slots, or machining down the flat face where the caliper mounts to achieve the same effect.

The other option is to use additional spacers on the axle inside the dropout so that it now protrudes the required 10mm or 15mm past the disk rotor. This will increase the axle length and require some small spreading open of the fork in order to fit. It is usually no problem with rigid forks but could be a concern with suspension forks as the telescoping tubes would no longer be parallel.

Disk Caliper Clearance

The other common disk related concern is having sufficient room between the disk rotor and the side of the hub motor for the caliper to fit. This is especially common with the larger diameter direct drive motors. Even if the disk rotor aligns properly in the dropout, the outside of the disk caliper might rub against hub motor itself.

In many generic direct drive motors (like the 9C+ and MXUS motors), the disk boss sits about 14-15mm past the motor side plate. There are some mechanical disk calipers that are narrow enough to fit in that gap, but most brand name hydraulic calipers require at least 17-18mm of room.

There are several solutions to this issue;

1) Use a narrower caliper. We used to carry an Alhonga brand caliper that was only 14mm. It's not very easy to find the spacing requirement as a published spec, so usually that means either physically testing units at a local bike shop or trying to deduce from pictures online.

2) Switch to a larger diameter rotor if there is more room further away form the center of the axle and get the required caliper adapter. This solution is shown in the image above.

3) Install spacers under the disk rotor and on the axle shoulder. This will provide the caliper clearance and proper rotor alignment, but it will also increase the overall axle length requiring more spreading to get the wheel to fit.

At Grin, we've made it a point since 2019 to only carry hub motors that have proper disk rotor alignment (10mm front / 15mm rear) and at least 18mm of caliper clearance, so for our customers these fitment issues will be a thing of the past.

Filing Dropout Slot

If you have a bike with slotted dropouts and a hub motor with standard 10mm axle flats, but the axle is just a bit too wide to fit in the slot, don't despair. This is a very common situation. All you need to do is get a hand file and enlarge the slot until the axle just slides in. If you are anxious about removing any metal from their bike frame, then you can instead file the axle flats on the motor to be a bit narrower.

We'd estimate that about 20-30% of bike frames require at least a little bit of filing.

Frame Spreading

Many of the fitment solutions above involve spreading open the frame to fit a wider hub axle. Almost any frame can be spread open by a few mm if necessary, and that includes carbon fiber and Aluminum even if you've read elsewhere that is a no-no. So if you have a hub motor that is 138mm but your frame is 135mm, don't worry, it will fit just fine with some very small effort to pull the dropouts apart while you insert the motor. That's just 1.5mm on either side, it's well within the elastic deformation of the frame materials and is not going to crack or damage anything. Your frame flexes more than this when you stand on the cranks grinding up a hill.

But if you need to spread the frame a lot, like 5mm or more, then you'll want to cold set the frame to a larger size and that is something usually reserved for steel frames only. Sheldon Brown (Rest In Peace good man) has an excellent tutorial and guidelines for frame spreading. The only frames that are nearly impossible to spread to some degree are cargo bikes where the rear stays bridge together on the back side, like the Surly Big Dummy or Xtracycle Edgerunner.

Carbon Fiber and Aluminum

There are many voices on the internet saying that you should never install a hub motor on aluminum or carbon fiber bike frames, that the motor forces will tear the frame apart and cause certain failure. This not in general true. As we keep trying to point out, the pulling forces and stresses that a hub motor puts on a bike are much much less than the forces caused by disc brakes, or the stresses caused from hitting bumps and potholes on a road. This false belief stems from failed motor installations that don't have a torque arm installed and are instead relying on the dropout slot itself to resist all the rotational torque of the axle. In this approach even steel frames can still suffer axle spin-out.

As long as you have a properly fitted torque arm to transfer axle torque to the bike frame, then the material of the frame and dropout is not much of an issue. If the frame is designed to cope with the forces present from a normal bicycle wheel with disc brakes then it will cope with an ebike hub motor just fine too. Our customer base is filled with countless electrified carbon, aluminum, magnesium, and even bamboo bike frames as testament to this.

Canadian

Canadian