Hub Motor Options

Overwhelmed by all the different motor options? Even though it seems like a lot, we have a well curated list of motor models that allow us to accommodate almost every bike type and power requirement. This page is intended to give a good summary review of each model and how they compare in different applications.

Basic Motor Table

| Motor Series | Motor Type | Weight | Notes |

| Bafang G310 / G311 | Geared | 2.3 kg (2.5 kg Rear) | Quiet Helical Gears |

| Shengyi SX1 / SX2 | Geared | 3.0 kg (3.2 kg Rear) | Quiet Helical Gears |

| eZee | Geared | 3.8 kg | Front, Freewheel or Regen Option |

| GMAC | Geared | 3.8 kg | Rear Regen Only |

| Bafang G62 | Geared | 4.9 kg | Fatbike |

| Crystalyte SAW20 | Direct Drive | 3.0 kg | Folding Bike (75mm) |

| Original Grin All-Axle | Direct Drive | 4.0 kg (4.3 kg Rear) | Supports All Dropouts, including Thru-Axle |

| Max45 All-Axle | Direct Drive | 6.0 kg (6.3 kg Rear) | Front and Rear Fatbike Dropouts, Slotted and Thru-Axle |

| Nine Cont. FH212 / RH212 | Direct Drive | 6.4 kg (6.7 kg Rear) | Good Power for Price, if a bit heavy |

Our most popular geared hub motor conversion systems are the Mini G310/G311 or slightly larger SX motors for those wanting a lighweight and silent setup, and the higher end GMAC and eZee kits for those wanting awesome hill climbing torque and regen. For direct drive hub motors our All-Axle hub now account for a majority of our kit sales, while interest in the lower cost and heavier RH212 / FH212 has been on the decline though they still have a use case.

In addition to these common options, we also have a number of specialized kits for niche applications; such as the SAW20 with 75mm axles folding bikes, Wheelbarrow motors for material moving, and the G62 motor for fatbike conversions with 170-195mm rear dropouts. For a detailed list on what motors would be compatible with your particular bike frame, have a read of our Bike Compatibility Guide. Here’s a summary breakdown of the current packages that we've put together at Grin, from smallest to largest.

Crystalyte SAW20

| Motor Weight | 3.2 kg |

| Typ. Power | 250-500 W |

| Motor Type | Direct Drive |

| Mounting | Front Only |

SAW20 Kit: This is a small direct-drive hub motor designed for folding bikes with 75mm forks. It’s larger in diameter and heavier than the small geared motors but maintains a more narrow profile. We have a special tiny axle variant prelaced in 16" (ETRTO 345) rims for use with Brompton bikes, and a generic axle option for suitable for most 20” Dahon/TERN bikes.

Bafang Mini Geared G3 Series

| Motor Weight | 2.55 kg |

| Typ. Power | 250-500 W |

| Motor Type | Geared |

| Mounting |

Front / Rear |

Bafang G311 / G310 Geared Kit: These are very small geared motors that are well-suited for people who want a minimal level of assistance in a discrete setup. Being a geared kit, they freewheels when not in use, and being lightweight they have little effect on the characteristics of a bike. The G310 is a rear cassette motor and both it and the front use the nearly silent helical gears with high reduction ratios. See our G310/G311 Product Page for more details.

Shengyi SX Series

| Motor Weight | 3.0 kg |

| Typ. Power | 250-500 W |

| Motor Type | Geared |

| Mounting |

|

Shengyi SX Geared Kit: These are geared front and rear hub motors that are slightly larger and more powerful than the Bafang G31X series. They also feature a silent helical gear reduction but have a more robust motor construction style making them better suited for modest power levels and hill climbing. See Shengyi SX Product Page for more details.

G62 Fatbike

| Motor Weight | 4.95 kg |

| Typ. Power | 600-1200 W |

| Motor Type | Geared |

| Mounting |

Rear Only |

G62 Fatbike Kit: The Bafang G62 is a rear geared hub motor specifically sized for fatbikes with extra wide rear dropouts. It uses a cassette freehub system and has a power and torque output similar to the eZee and GMAC motors. This motor is available in two axle lengths to support both 170-175 dropouts, or the longer 190-195mm dropouts used in even fatter fat bikes. We offer an option for a locked clutch mod for those wanting regen and/or reverse capabilities.

eZee

| Motor Weight | 3.8 kg |

| Typ. Power | 600-1200 W |

| Motor Type | Geared |

| Wheel Sizes |

Front and Rear |

eZee Kit: The eZee system is our popular high performance geared motor setup, and has about twice the power and torque capability of the Bafang G31X motor (500-1000 watts), making it better suited for steeper climbs and cargo hauling. The ~4kg motor is available in both front and rear options, and the front model is available without a clutch for regen. See the eZee motor info page for full details

GMAC

| Motor Weight | 3.8 kg |

| Typ. Power | 600-1200 W |

| Motor Type | Geared |

| Mounting |

Rear Only |

GMAC Kit: The GMAC motor is similar in performance and torque capability to the eZee motor, but it has a locked clutch instead of an internal freewheel making the motor capable of regenerative braking too. This motor is recommended in cases where regen is more important than freewheeling and the high power to weight ratio of a geared motor is desired. It has an integrated torque arm and uses a round M10 axle simplifying the installation. See the GMAC info page for more details.

Grin All-Axle

| Motor Weight | 4.0 kg |

| Typ. Power | 500-1000 W |

| Motor Type | Direct Drive |

| Mounting |

Front and Rear |

Grin All Axle Kit: The All-Axle hub motor is developed and manufactured by Grin at our Vancouver shop, and among the only hub motors on the market natively compatible with thru-axle dropouts. It is over 2kg lighter than comparable power generic direct drive hub motors, and a wide selection of axle inserts provides compatibility with nearly all quick release and thru-axle dropout standards. The rear version features integrated PAS and Torque sensors for a simple installation. This is an awesome and versatile front hub choice if it is within your budget. For more info see the All-Axle hub page.

Max45 All-Axle

| Motor Weight | 6.0 kg |

| Typ. Power | 750-2000 W |

| Motor Type | Direct Drive |

| Mounting |

Front and Rear Fatbike |

Grin Max45 All-Axle: This is the big cousin to our original All-Axle hub motor but with a larger 45mm internal motor width providing 66% more torque and power capability. That extra width makes it too wide to fit in normal bike frames, but it's a perfect size for fatbike frames which have 135-150mm front fork spacing and 170-197 mm rear dropouts. As expected, we have adapters for all of those standards. And we do have a Max45 single speed option that does fit in 135mm frames for setups that don't require a rear gear set. See the All Axle hub page.

FH212 / RH212 Kit

| Motor Weight | 6.7 kg |

| Typ. Power | 600-1200 W |

| Motor Type | Direct Drive |

| Mounting |

Front and Rear Slotted Dropouts |

RH212 FH212 Kits: We'd been bugging Nine Continent for many years to produce a rear kit that uses a cassette freehub system rather than a threaded freewheel, and which also had proper disk rotor fitment and caliper clearance with 135 mm dropout compatibility. We finally got our wish in 2018 with the 212 mm motor series, which also has a deeper stator and higher pole count (52 rather than 46 magnets) than the standard 205mm direct drive hubs for higher torque output. See the H212 info page for more details.

Benefits of a Hub Motor

Hub motors are the most versatile and easiest way of converting a bike or trike over to electric assist. Unlike aftermarket mid-drive systems such as the Bafang BBSHD, they don't put any additional stress on your existing drivetrain and operate with complete independence of your pedal transmission. If your chain breaks, derailleur snags, cogs gets loaded in snow etc. the hub motor will continue to propel the bike even when your legs can't. Not to mention the huge advantages of having regenerative braking.

There is a considerable amount of misinformation in the online ebike space about mid-drive bikes being superior than hub motors. In most cases the arguments are false generalizations, and result of people extrapolating from the fact that most low-cost factory ebikes are hub motors and expensive brand bikes are Bosch or Shimano mid-motors. Unless you are mostly into recreational trail riding and offroad mountain biking, a suitably powerful hub motor will usually serve you needs just as well with far lower maintenance and better dependability.

Have a look at our Why Hub Motors article for a more detailed explanation on the benefits of hub motor systems, especially for commuter ebikes.

Geared vs Direct Drive

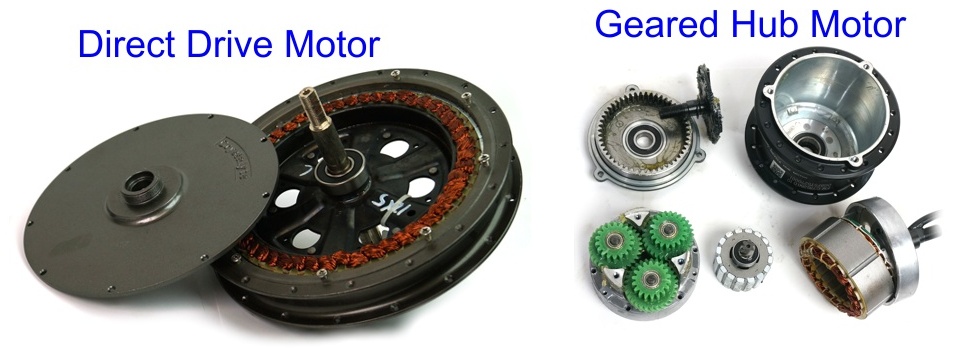

Broadly speaking, there are two classes of hub motors, geared and direct drive.

In a geared hub, the motor spins internally at a high RPM and a planetary gear transmission reduces this to the low RPM of the bike wheel. This allows for a relatively small electric motor to provide substantial wheel torque. Geared hub motors usually weight between 2-4kg and are small in diameter, allowing them to remain pretty discrete on the bike. For a number of reasons, almost all geared motors also include a freewheeling clutch so that the wheel will spin freely and not turn the motor over if you are coasting.

In a direct drive hub motor, the hub IS the motor, so there is no internal gearing. The wheel RPM is the same as the motor RPM. This has enormous advantages in terms of simplicity with no moving parts inside, but in order to produce adequate torque the direct drive motors need to be large in diameter and relatively heavy. They are typically between 4-9kg and over 20cm (8") diameter. Direct drive motors don't have a clutch, allowing them to do regenerative braking, but this also means that there is some small motor drag while coasting as the magnets are always moving past the stator iron.

| Pros of Geared Motor | Pros of Direct Drive |

| ⦁ Discrete smaller diameter | ⦁ Better high speed efficiency |

| ⦁ Light Weight | ⦁ Regenerative braking |

| ⦁ Freewheeling | ⦁ Silent operation |

| ⦁ Better hill climbing efficiency | ⦁ No moving parts to fail |

In general, we find that geared motors are most often preferred by people who value their smaller size and weight, who require a hub with good efficiency during hill climbing, and for whom the ability to coast with zero drag outweighs the benefits of regenerative braking.

Direct drive hub motors generally shine most in applications where high speed is needed, where regenerative braking is useful, where complete silence is paramount, and where the additional motor weight is not seen as too problematic.

The release of our All-Axle motor has shifted the equation for many people, as it is only marginally heavier that comparable geared hubs like the eZee and GMAC.

For geared motor kits we have the small Bafang G310 (rear) or G311 front, the slightly larger Shengyi SX1/SX2, and the very powerful eZee and GMAC. For direct drive motors we have the premium lightweight and fits-on-all-bikes Grin All Axle hub on one end, and the heavier by value priced FH212 and RH212 from Nine Continent on the other.

Regenerative Braking?

Regenerative braking involves using the motor as a brake to assist in slowing the bike down without wearing your mechanical brakes. This typically results in a 3-8% increase in your range from recaptured energy and a massive reduction in the frequency with which you need to adjust and replace your brake pads. There is no downside or tradeoff whatsoever to having regen if you have a direct drive hub motor. For some of the geared motors we offer the option of regen or not, and depending on how you feel about freewheeling vs reduced brake wear you may be swayed one way or the other. For more info we recommend watching this video here.

Regenerative braking involves using the motor as a brake to assist in slowing the bike down without wearing your mechanical brakes. This typically results in a 3-8% increase in your range from recaptured energy and a massive reduction in the frequency with which you need to adjust and replace your brake pads. There is no downside or tradeoff whatsoever to having regen if you have a direct drive hub motor. For some of the geared motors we offer the option of regen or not, and depending on how you feel about freewheeling vs reduced brake wear you may be swayed one way or the other. For more info we recommend watching this video here.

Our Phaserunner and Baserunner controllers have variable regenerative braking, and there are various methods available to modulate and vary the braking force; from proportional brake levers to bidirectional throttles to back-pedal rotation.

Front vs Rear or Both?

The next big question for hub motor selection is whether to put the motor on the front or the rear of the bike. There is a TON of misinformation on the internet and reddit/endless-sphere in particular which says you should always choose a rear hub motor and that front hub motors are dangerous/unstable/ill-advised. This is not generally true. Our sales are almost exactly 50:50 split between front and rear setups and customer satisfaction is the same in all cases. The smaller geared motors tend to be more front than rear, while the larger direct drive hubs tend to sell more rear than front.

The next big question for hub motor selection is whether to put the motor on the front or the rear of the bike. There is a TON of misinformation on the internet and reddit/endless-sphere in particular which says you should always choose a rear hub motor and that front hub motors are dangerous/unstable/ill-advised. This is not generally true. Our sales are almost exactly 50:50 split between front and rear setups and customer satisfaction is the same in all cases. The smaller geared motors tend to be more front than rear, while the larger direct drive hubs tend to sell more rear than front.

Usually we would recommend a front hub unless there is a compelling reason to put the motor on the rear since it's an easier installation. There is also generally no problem at all installing a hub motor on a bike with suspension forks, carbon forks or whatever. So long as you have a properly installed torque arm so that the axle rotation is not spreading the dropouts, the pulling forces that a motor puts on a fork are WAY smaller than the forces present when slamming on the front brakes or hitting a pothole.

The benefits of a front hub are as follows:

- No conflict or change to your drivetrain

- Ability to use internal gear hubs on the rear

- Simpler installation

- Better weight distribution if battery is on the rear

The main downside of a front hub relates to the fact that on most bicycles, a majority of the rider weight is on the rear wheel rather than the front wheel, so the amount of traction available on the front wheel is not as high and it can be possible for the wheel to skid out at full throttle. Riding on pavement this only becomes an issue at fairly high power levels (>1000 watts), but when climbing hills on loose gravel or dirt roads, you can end up with the front wheel skidding pretty easily even at fairly modest powers unless you deliberately lean over the handlebars.

Downsides to a Front Hub:

- Limited traction for high power (>1000 watts) or loose gravel roads

- Not entirely discrete, especially direct drive

- Always requires external PAS or Torque sensor on bottom bracket

For rear installations, the motor is better tucked away with the cogs and pannier bags, and it is possible to run at very high torque levels without losing traction. However, the motor must also tie into the mechanical drivetrain.

Benefits to a Rear Hub:

- Looks most discrete

- Possibility to have torque sensor integrated in motor, without need for bottom bracket sensor

- Almost no limit to power capability in terms of traction and handling

Downsides to a Rear Hub:

- No opportunity to use internal gear hubs

- Drivetrain compatibility concerns (freewheel vs freehub, 7,8,9,10,11 speeds, road vs mountain cassettes)

It used to be that we would usually recommend a front hub unless you had a compelling reason to get a rear motor, mostly because the older rear hub motors used screw on freewheels and often had drivetrain compatibility issues. But now all our rear motors use Cassette Freehubs and our All-Axle even has a SRAM XD driver option, and so we are more inclined to suggest a rear hub motor as default. This is especially true for the All-Axle kits, where the rear motor provides an integrated PAS and Torque sensor eliminating the annoying step of bottom bracket replacement.

Another consideration is wheel size, and in vehicles where the front and rear wheels are different diameters you will always get the best motor performance putting the hub drive in the smaller of the two wheels.

Dual Hub Motors

Dual front/rear hub motors on a bike is an excellent way to achieve higher power levels than a single hub motor can produce, and is especially useful in cargo bike or load hauling applications. When you run two brushless motor systems on the bike, each motor requires its own motor controller (there is no way around this) but the throttle signal would typically be split to run both motors equally. For more specific information on setting up a multi-motor system, see our multi-drive info page here. We do not provide a dropdown 'kit' for dual motor systems. Normally we would recommend purchasing one system as a kit, and then purchasing the second motor and motor controller a la cart, along with the appropriate dual controller splitter cable.

Dual front/rear hub motors on a bike is an excellent way to achieve higher power levels than a single hub motor can produce, and is especially useful in cargo bike or load hauling applications. When you run two brushless motor systems on the bike, each motor requires its own motor controller (there is no way around this) but the throttle signal would typically be split to run both motors equally. For more specific information on setting up a multi-motor system, see our multi-drive info page here. We do not provide a dropdown 'kit' for dual motor systems. Normally we would recommend purchasing one system as a kit, and then purchasing the second motor and motor controller a la cart, along with the appropriate dual controller splitter cable.

Wheel Lacing

Grin used to source most of our hub motors prelaced overseas by eZee, Crystalyte, Nine Continent etc. and only offered custom hand-built wheels as a special option. But we found the quality control of prelaced hubs hard to guarantee, and even if we hand tweaked the spoke tension and truing of the prebuilt motors before shipping we still had a fairly high rate of customers experiencing spoke breakage. Meanwhile our own hand built wheels had a nearly flawless track record by comparison.

Grin used to source most of our hub motors prelaced overseas by eZee, Crystalyte, Nine Continent etc. and only offered custom hand-built wheels as a special option. But we found the quality control of prelaced hubs hard to guarantee, and even if we hand tweaked the spoke tension and truing of the prebuilt motors before shipping we still had a fairly high rate of customers experiencing spoke breakage. Meanwhile our own hand built wheels had a nearly flawless track record by comparison.

As a result of this experience, we now exclusively stock only unlaced bare hub motors and do all of our kit wheelbuilds by hand, using the best quality Sapim 13/14g butted spokes and applying all the expertise we've acquired over the years to make nearly bombproof wheels. It means a built-up kit form Grin will cost more than most other hub motor suppliers, but in exchange you can have a vast choice of rim options and full peace of mind that you won't be randomly popping spokes down the road.

If you want the kit at a budget, you can absolutely do the wheel lacing yourself and order just the hub motor and spokes and either reusing your original rim or getting one locally. This also greatly reduces the shipping cost to places like Australia and Europe, as the kit can be sent out in a much smaller box size.

Power Rating

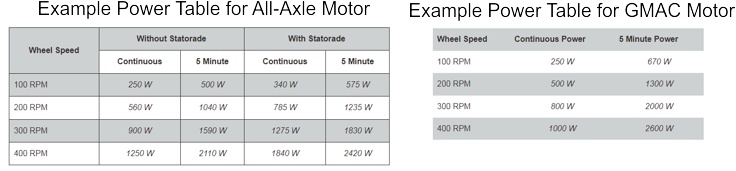

Most in the ebike industry erroneously catalog and reference motors as having a certain power, and you will see people endlessly talking about having an ebike with a 250 watt motor, or a 500 watt motor, or a 1000 watt motor. This is neither accurate nor meaningful. The power capability of an electric motor depends on both the RPM it is running at AND on how long you need it to run for. It is not a single number and it can only be represented by a full table of values for different conditions.

Every motor also has a reasonable set of conditions where the continuous output power is in fact 250 watts, and so for those who require a 250 watt power rating on their motor to facilitate compliance we provide a laser engraving service. Please do not limit your motor choice based on a perceived motor power rating. Make sure you choose a motor that has sufficient torque capability to move you up the grade hills you expect to enounter.

À-la Cart or Premade Kit Bundle?

All of our hub motor models are available by themselves, and you are free to purchase the parts you need to build up a kit. But for most people it is easiest to use one of our conversion kit bundle pages where you can pick and chose among all the compatible options of controller, battery, torque arm etc. All motors are available to purchase as a Barebones Kit, a SuperH Kit, or a CA3 Kit. For details on that see our Kit Types page.

Canadian

Canadian