🇨🇦 All-Axle Hub Motor

The Grin All-Axle Hub Motor

One Family, Every Hub Motor You'll Ever Need

The Grin All-Axle is our family of direct-drive hub motors designed for compatibility with all varieties of rear and front mounting standards used in the bike world today. From quick-release dropouts to various 12, 15, and 20mm thru-axles standards to even single side mounting. In one product we:

- Solve the compatibility problem between hub motors and modern bike frames

- Provide the benefits of direct drive without the traditional heft

- Simplify the installation with integrated torque arms and torque sensors

Why Direct Drive?

We not only like hub motors, we're big fans of direct drives! Direct drives are:

- Smooth and silent - almost noiseless with no gears to grind

- Extremely reliable with minimal moving parts (clutches, gears) that may fail. We have customers who have clocked over 50,000 kilometres with no issues

- Regenerative braking capable, saving you brake pads and returning brake power for more range

Features

- Both FRONT and REAR models available

- Both Original width (27mm) and Max45 models (45mm) available.

- Lightweight 4.0 kg for Original / 6.0 kg for Max45, vs ~6kg and ~9kg for comparable generic DD motor

- 0.35mm Laminations for low motor drag when pedaling unassisted

- Integrated Torque Arm with secure frame mounting clamp

- Uses 32 Spoke Holes for vastly more in stock rim options

- Min 18mm Disk Caliper Clearance fits most (but not all) calipers without spacers

- Statorade Compatible with side cover injection port

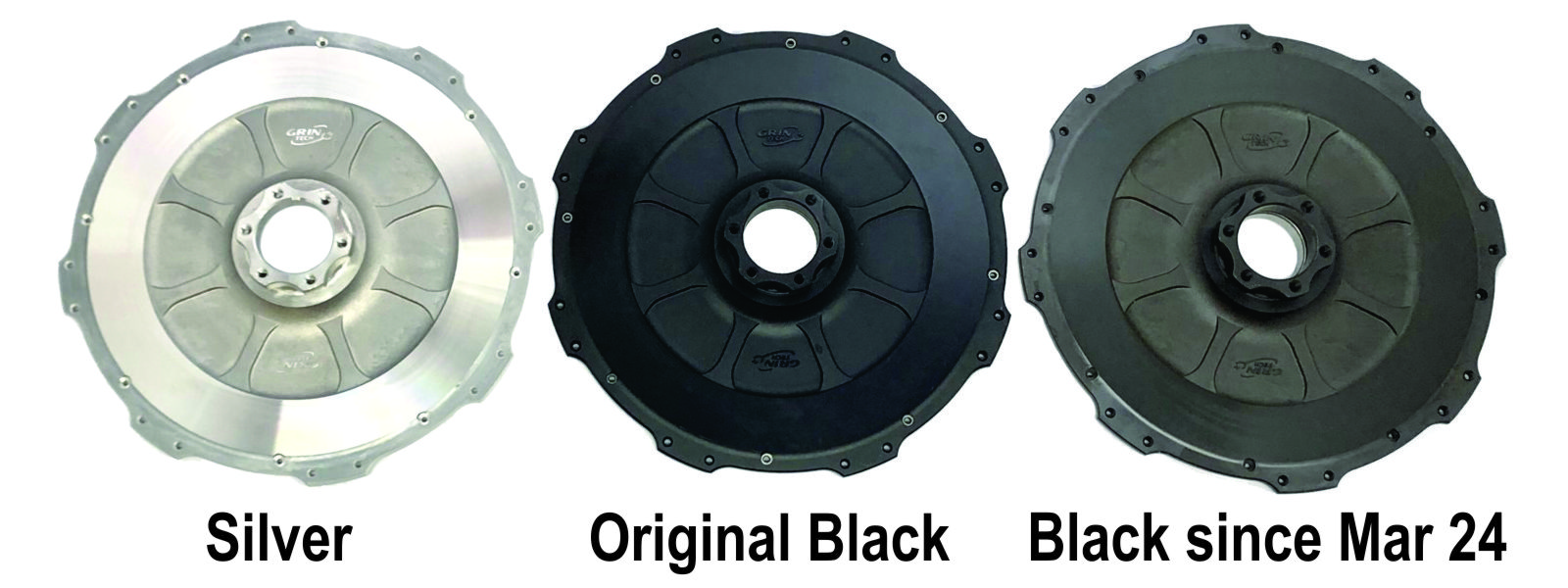

- Available in both metallic silver and black anodized finish

- Designed and Assembled in Canada

Rear Specific

- Built-In Torque and PAS Sensor. No need for bottom bracket torque or cadence sensors

- Support both Shimano HG and SRAM XDR cassettes, with XDR for wide range 11-12 speed

- Fits Most Rear Dropout Standards (135, 145, and 160mm quick release, 12x142, 12x148 Boost, and 12x157 Superboost Thru Axle, and Max45 in 170&190mm Quick Release and Thru-Axle Fatbikes)

Front Specific

- Fits Almost All Front Fork Standards (100mm and 135mm Quick Release, 12mm, 15mm, 15mm Boost, and 15mm x 150 Thru-Axle)

- Compatible with Single Side Installation on many trike and quad vehicles

Models

There are 5 distinct mechanical models of the All-Axle motor currently in production summarized in the table below. Each model is available in several winding speeds.

| Model | Weight | Stator Width | Axle Bore | Frame / Dropout Compatibility |

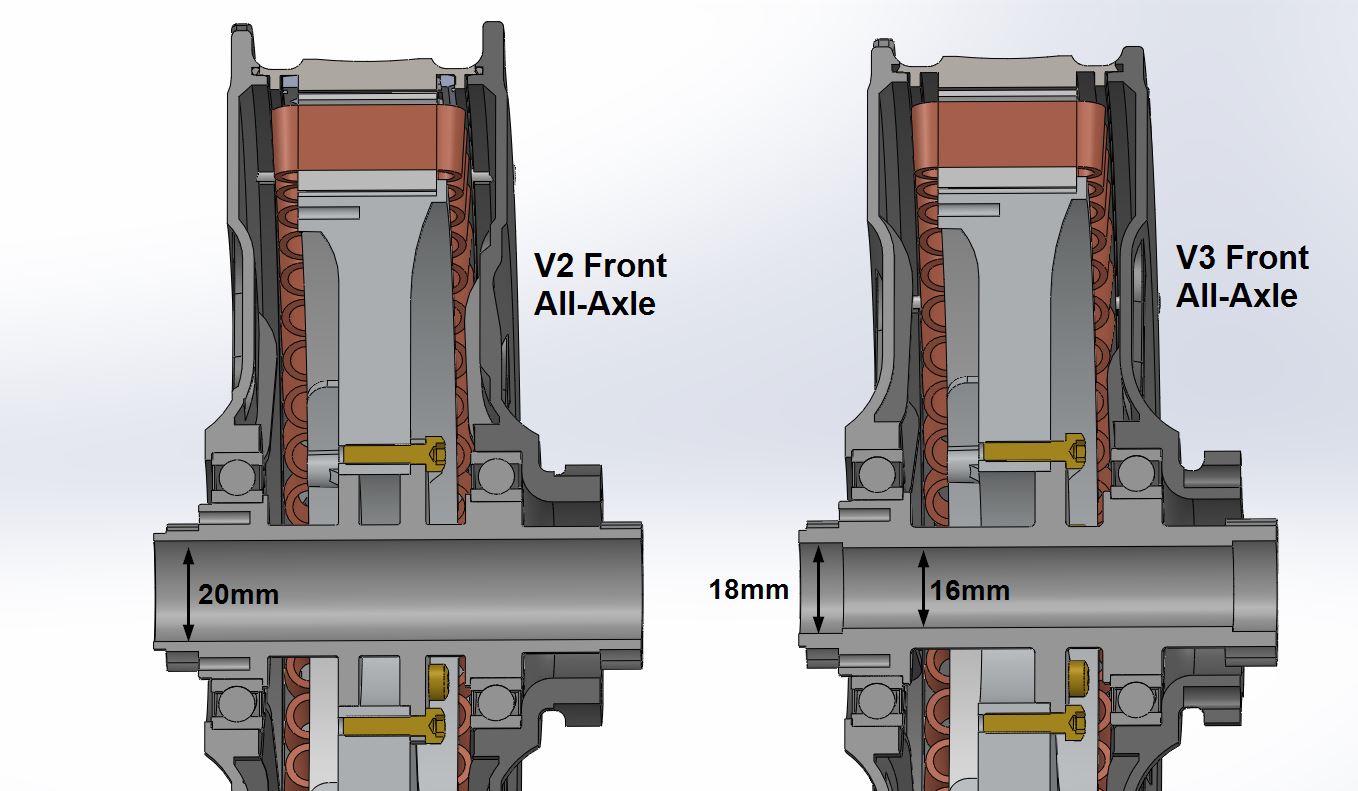

| V2 Front | 4.0 kg | 27mm | 20mm | Only recommended for old 20x110 mm Thru-Axle suspension forks, or single side applications requiring 20mm axle mount. |

| V3 Front | 4.0 kg | 27mm | 16mm | Slotted Dropouts: 100mm, 135mm Thru Axle: 12x100, 15x100, 15x110, 15x150 |

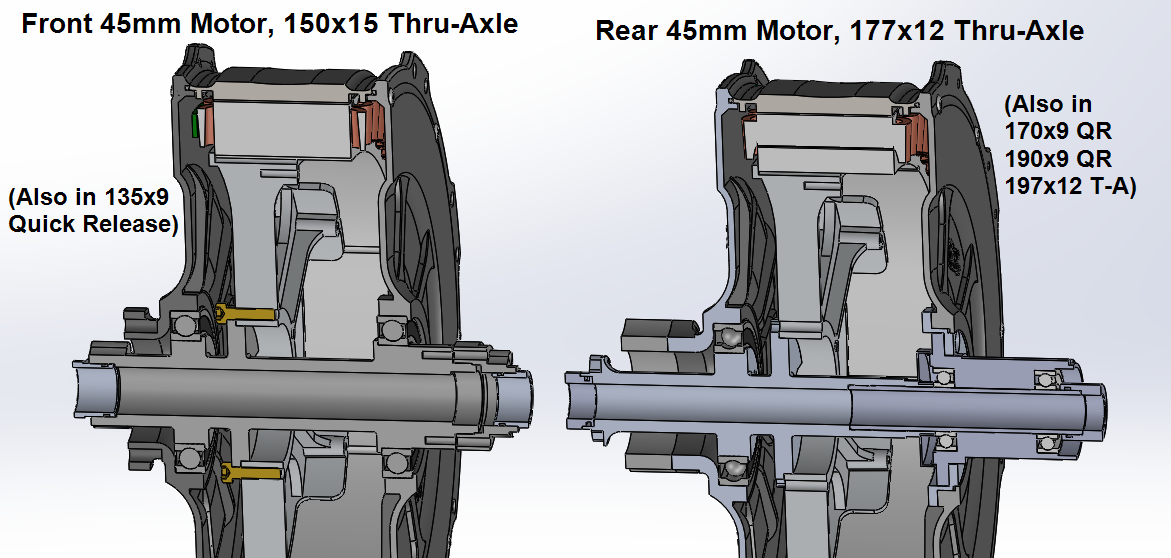

| Max45 Front | 6.0 kg | 45mm | 16mm | Slotted Dropouts: 135mm Thru Axle: 15x150 |

| V3 Rear | 4.3 kg | 27mm | 12mm | Slotted Dropouts: 135mm,145mm (tandem), 160mm (Santana Tandem) Thru Axle: 12x142, 12x148 (Boost), 12x157 (Superboost), 12x167 (Santana) |

| Max45 Rear | 6.3 kg | 45mm | 12mm | Slotted Dropouts: 170mm (4" Tire), 190mm (5" Tire) Thru Axle: 12x177 (4" Tire), 12x197 (5" Tire) |

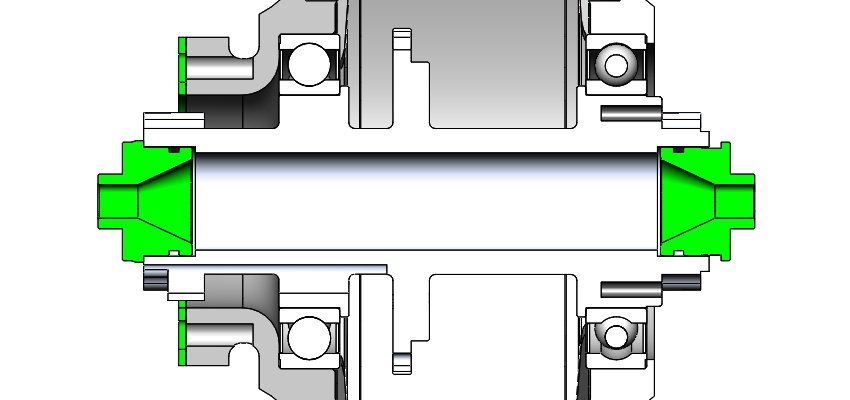

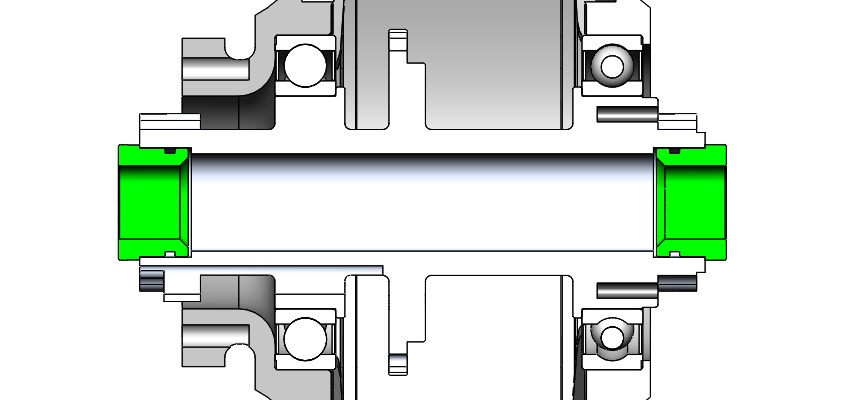

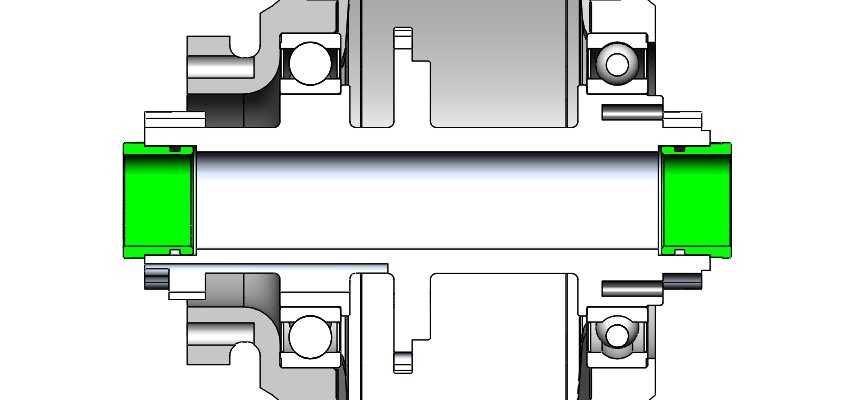

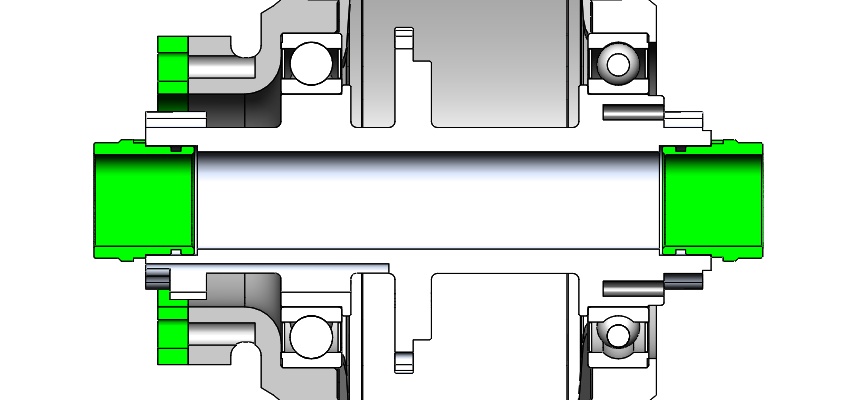

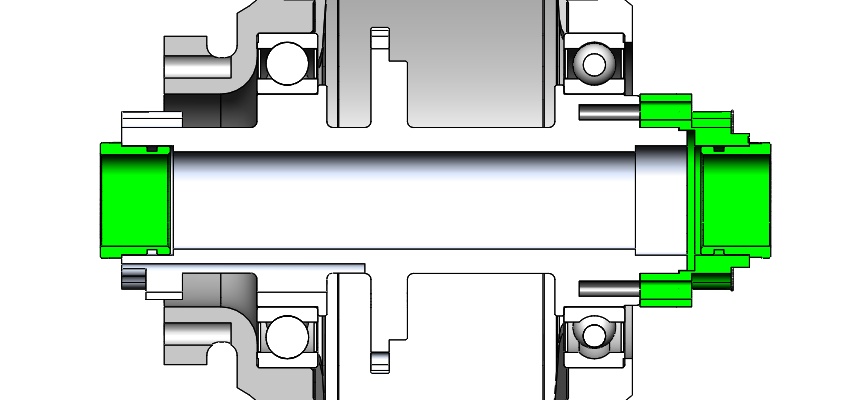

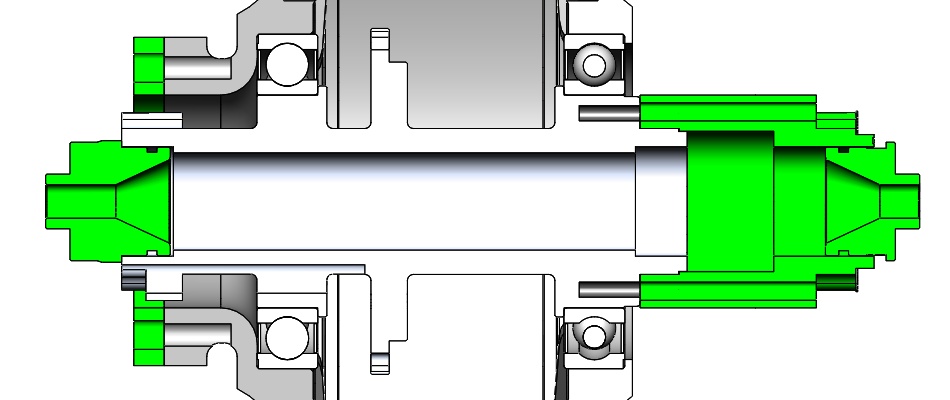

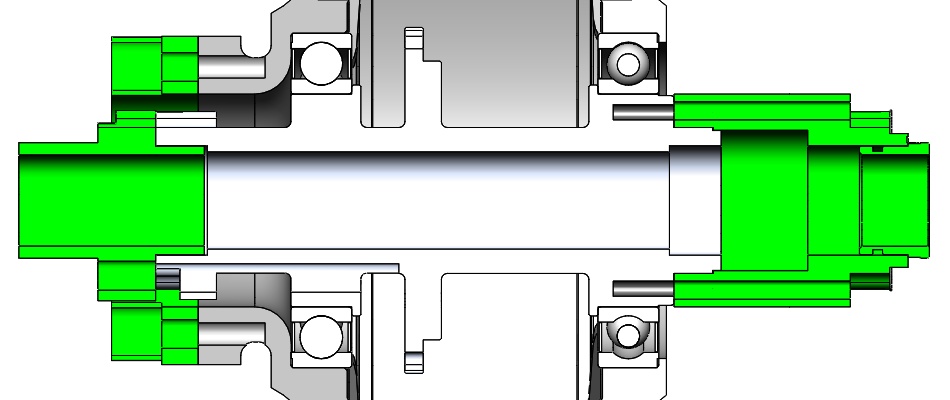

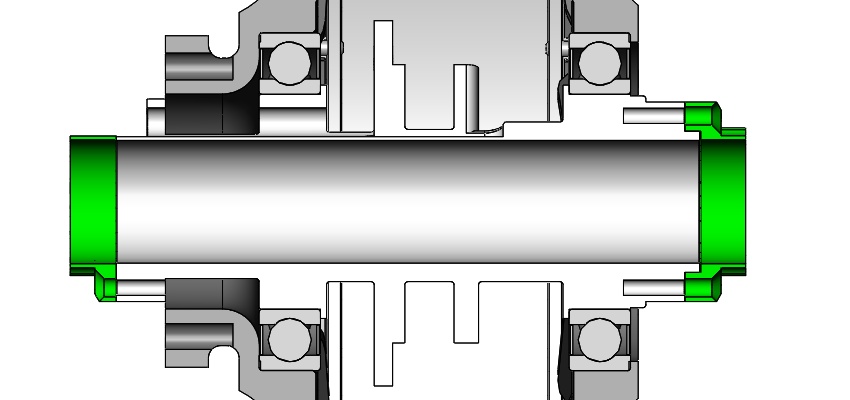

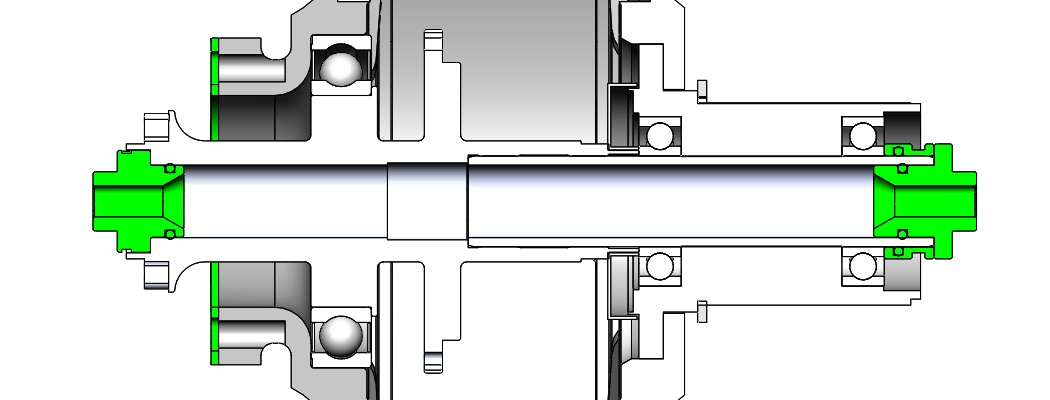

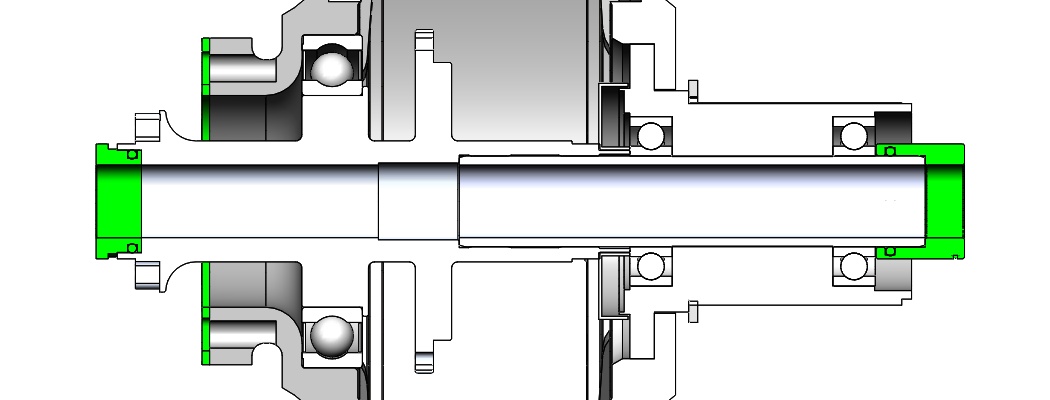

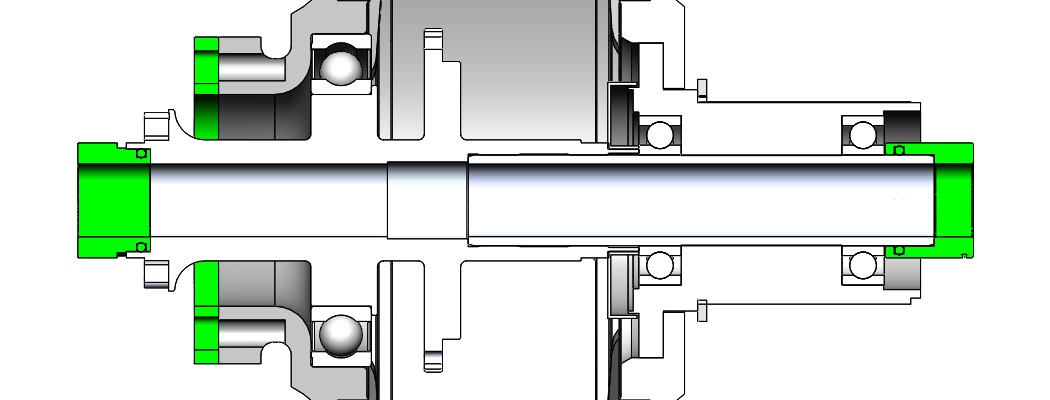

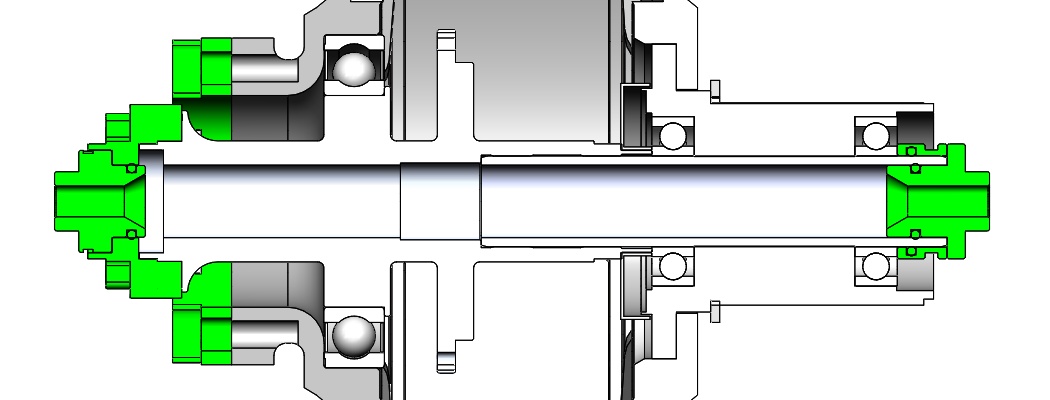

Axle Adapters and End Caps

Front Hub Adapters

The front motor fits various size dropouts through the use of different end caps and occasional axle extenders and disc spacers. Here is a summary of the options

|

Slotted Dropouts (100mm) |

|

These inserts allow the motor to fit in standard 100mm wide front forks with slotted dropouts using a regular quick release skewer to hold the motor in place. The vast majority of older bikes and new low to mid-range bikes will use this adapter |

|

12mm Thru-Axle |

|

The 12 mm thru-axle is a newer standard for road bikes to gain the stiffness and security benefits of a thru-axle wheel at a lower weight than the 15mm size common in offroad bikes. These forks have the standard 100mm dropout spacing. |

|

15mm Thru-Axle |

|

The 15mm front thru-axle was introduced for cross-country and mountain bikes when the original 20mm thru-axle standard of downhill bikes was seen as overkill. The regular 15mm thru-axle uses the same 100mm hub spacing and disk rotor placement as regular quick release hubs |

|

15mm x110 Boost Thru-Axle, Even |

|

The boost adapters are similar to the standard QR15 except that the left and right sides protrude an extra 5mm, making the overall hub 110mm wide instead of 100mm. This adapter set has the exact same dishing any of the 100mm adapters so does not require redishing the rim when moved between forks, but it also requires a 5mm spacer on the disc rotor for correct rotor alignment. |

|

15mm x 110 Boost Thru-Axle, Offset |

|

These alternative boost adapters have a 10mm extension on the left side of the axle, so all the extra width is on the left side. That results in a centered non-dished wheel lacing and eliminates the need for a disc spacer. It is a more optimal choice if the motor is only being used with a 110mm boost fork. |

|

Fatbike Slotted Dropout (135mm) |

|

Fatbike forks with slotted dropouts typically have a 135mm spacing, similar to regular rear dropouts. This adapter set includes a 35mm extension on the axle to support these forks with our regular 27mm motor model. The disc rotor on fatbike forks can be positioned either 10mm or 15mm from the dropout face, and so an optional 5mm disc spacer is included with the kit to support either standard. |

|

Fatbike 15mm x 150 Thru-Axle |

|

Fatbike forks with thru axles have a 15mm x 150mm sizing. This adapter set uses an axle extender and rotor spacer to fit the that standard, and both 10mm and 15mm roor spacings are supported via an optional 5mm disk spacer. |

|

20mm Thru-Axle (110mm) |

|

This is the original thru-axle fork standard created for downhill mountain bikes and popularized in the very early 2000's. It is still in use on large travel suspension forks for serious off-road machines, but has been mostly replaced by QR15 size in regular mountain bikes. These Axle Adapters space both the left and right sides equally to build up the extra 10mm length and are only compatible with the V2 front all-axle motors. |

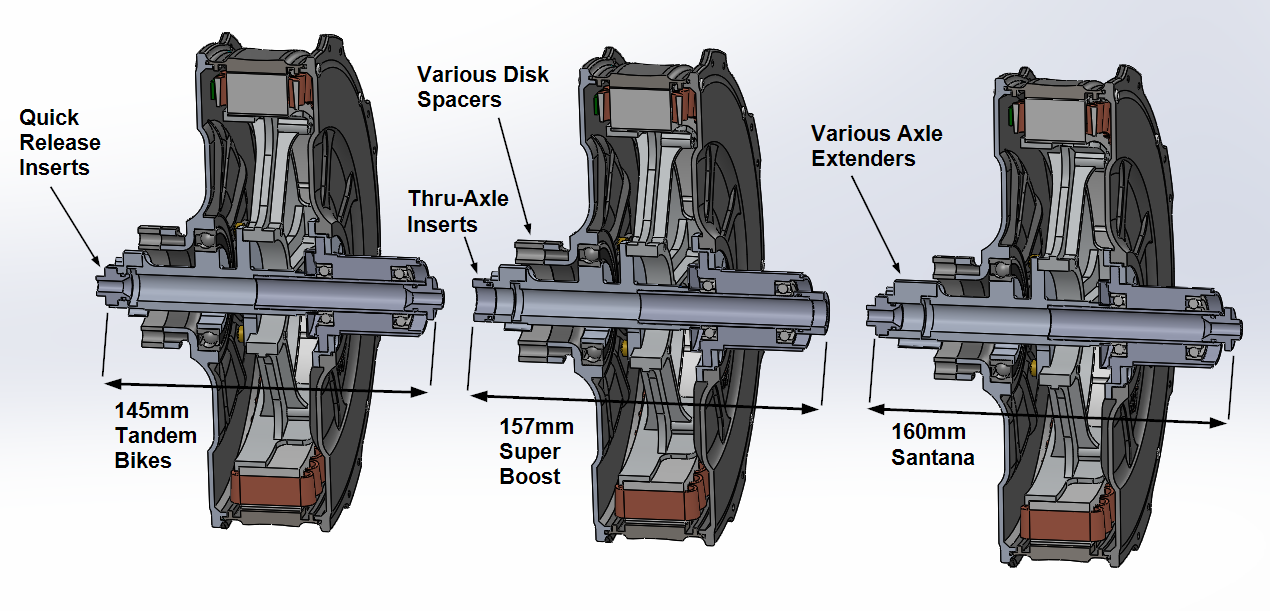

Rear Hub Adapters

The rear motors have a 12mm natural bore and uses end caps to fit the axle to either slotted dropouts or thru-axle frames.

|

135mm Slotted Dropout |

|

These end caps allow the motor to fit in a standard slotted rear dropout with a 135mm quick release skewer. The actual motor OLD is about 138mm. Notice that a spacer sleeve is included and must fit over the drive side axle to retain the cassette freehub. |

|

142mm Thru Axle |

|

With these end caps, the rear hub will fit in a thru axle frame with the original 142mm dropout spacing. Note that the actual V2 motor axle length is 145mm, while the V3 motor axle length is 143.5mm. This difference of a few mm wider than the nominal 142mm is mostly inconsequential. |

|

148mm Boost Thru Axle |

|

A slightly wider 'Boost' standard was created in the bike industry in order to provide greater stiffness and room for wider cassettes. The boost adapter has a longer length on the disc side end cap and a 4mm spacer under the disc rotor for proper alignment. |

|

145 Tandem Slotted Dropout |

|

This dropout standard is commonly used on tandem bicycles to support a wider flange spacing and a more symmetric lacing for a wheel that is less prone to buckling. The adapter kit uses an 8mm axle extender and a 9mm disc spacer. |

|

157 Super-Boost Thru Axle |

|

This is another rear hub thru-axle standard that is slowly gaining ground with mountain bikes to have better chainlines with wide tires and 1x cassettes. The adapter kit uses a 13mm axle extender and a 13mm disk spacer. |

|

160mm Santana Tandem |

|

This is a new tandem bike hub standard championed by Santana Tandems that uses slotted dropouts with a 160mm OLD. Both the freehub spacing on the right and the disk rotor spacing on the left are non-standard. It includes a 20mm axle extender a 9mm disc spacer plus the standard quick release end caps. |

|

167mm Santana Thru Axle |

|

This is the thru-axle version of Santana Tandem's 160mm dropout but using thru-axle end caps. |

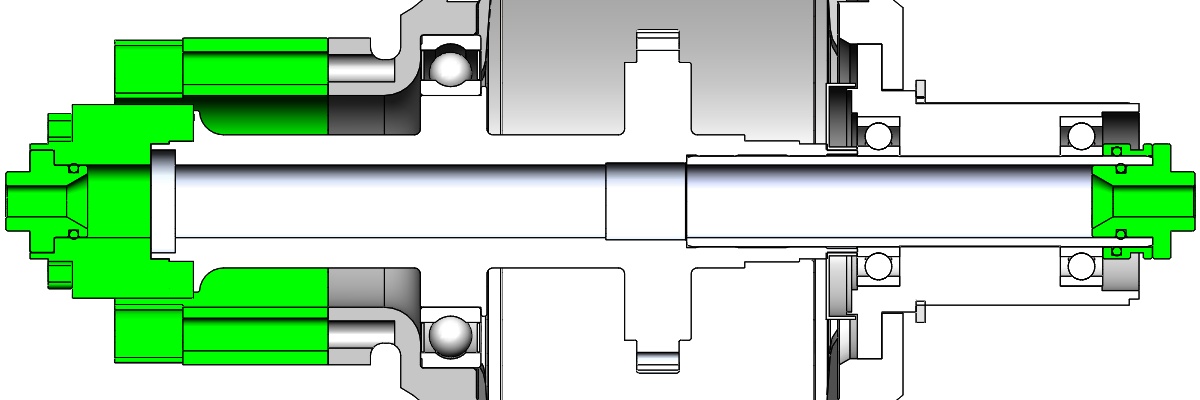

Max45 Hub Adapters

The wider Max45 motors are larger and heavier due to the wider stator and generally only fit fatbike bicycle frames. However a Max45 for regular width 135mm rear dropouts is in the works for regular bikes with just a single speed freewheel (See this Video).

|

Front 135mm QR |

|

These end caps and axle extender allow the Max45 Front motor to fit inside a 135 slotted dropout with a quick release skewer. Both 2mm and 5mm disc spacers are included for the two caliper standards used. |

|

Front 150mm Thru-Axle |

|

Fatbikes with thru-axle front forks use this adapter set, which includes a 24mm axle extender and 2 or 2+5mm disc spacer. |

|

Rear 170mm QR |

|

Fatbikes with slotted dropouts and ~4" wide tires usually have a 170mm to 175mm rear dropout width. This adapter set fits those bikes and uses a quick release skewer to hold the wheel in place. |

|

Rear 177mm Thru Axle |

|

Higher-end fatbikes use a thru-axle dropout on the rear. The 177mm spacing is common for fatbikes with 4" wide tires. |

|

Rear 190mm QR |

|

Fatbikes sporting wider 5" tires generally have a 190-195mm ewE dropout width. This adapter set extends the axle and disc rotor by 20mm to fit these extra wide fatbikes. |

|

Rear 197mm Thru Axle |

|

The thru-axle standard for Fatbikes with wide 5" tires is 197x12, our adapter kit includes the same axle and disc extenders as the 190mm kit but with thru-axle end caps. |

|

Rear 135mm QR |

|

This is a new new product being planned for 135mm dropouts that use just a single speed freewheel like cruiser bikes or Pinion geared mountain bikes, allowing them to use the larger and more powerful Max45 motor stator. Anticipated Summer 2025. |

Technical Specifications

| Original (27mm) Model | Max45 (45mm) Model | ||||

| Slow (8T) | Standard (6T) | Fast (5T) | Slow (5T) | Standard (4T) | |

| kV | 7.5 rpm/V | 10.0 rpm/V | 12.0 rpm/V | 7.2 rpm/V | 9.0 rpm /V |

| Phase to Phase Resistance | 268 mΩ | 145 mΩ | 100 mΩ | 155 mΩ | 102 mΩ |

| Phase to Phase Inductance | 680 uH | 380 uH | 260 uH | -- uH | -- uH |

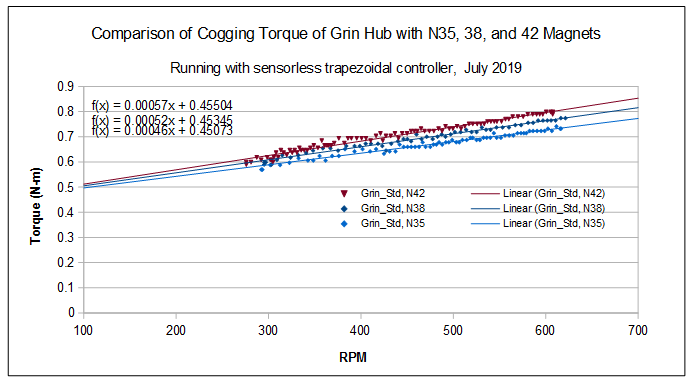

| Hysteresis Drag Torque | 0.6 Nm | 1.0 Nm | |||

| Eddie Current Drag Torque | 0.0005 Nm/rpm | 0.0008 Nm/rpm | |||

| Spoke Flange Diameter | 214 mm | 214 mm | |||

| Flange Spacing | 49 mm | 67 mm | |||

| Magnetic Pole Pairs | 23 | 23 | |||

| Motor Weight | 4.05 kg (8.9 lb) Front / 4.30 kg (9.4 lb) Rear | 6.0 kg (13.2 lb) Front / 6.2 kg (13.6 lb) Rear | |||

User Manuals

3D CAD Models

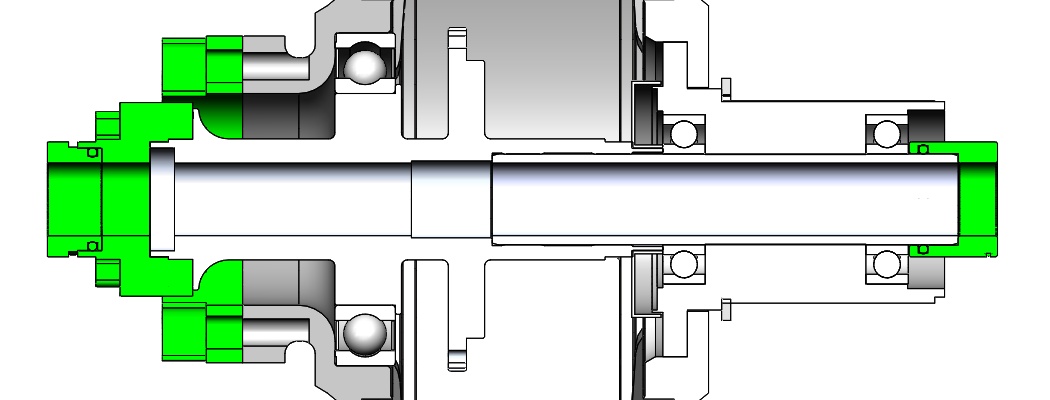

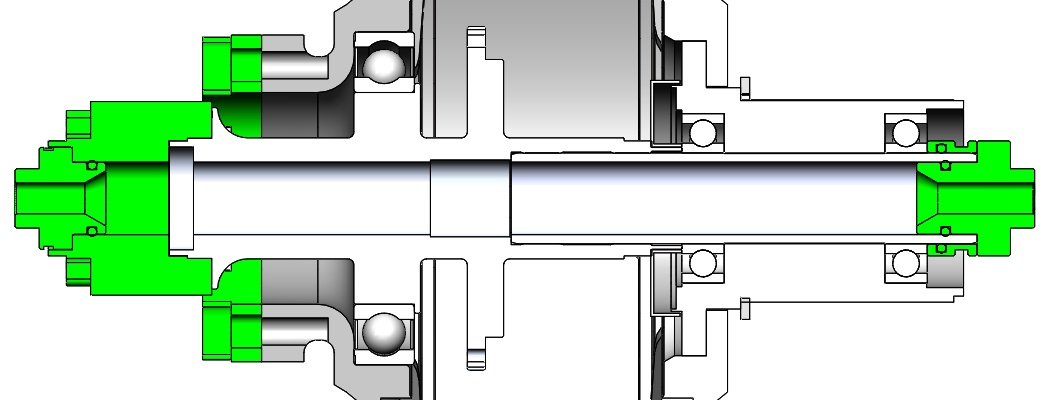

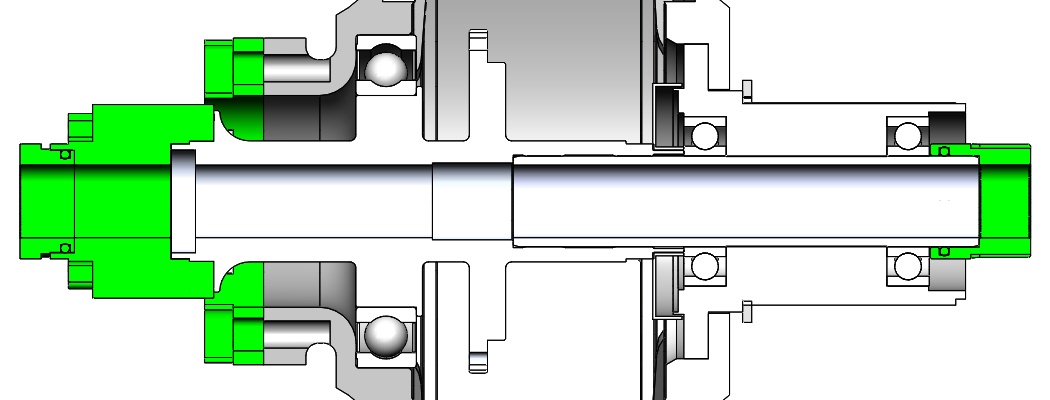

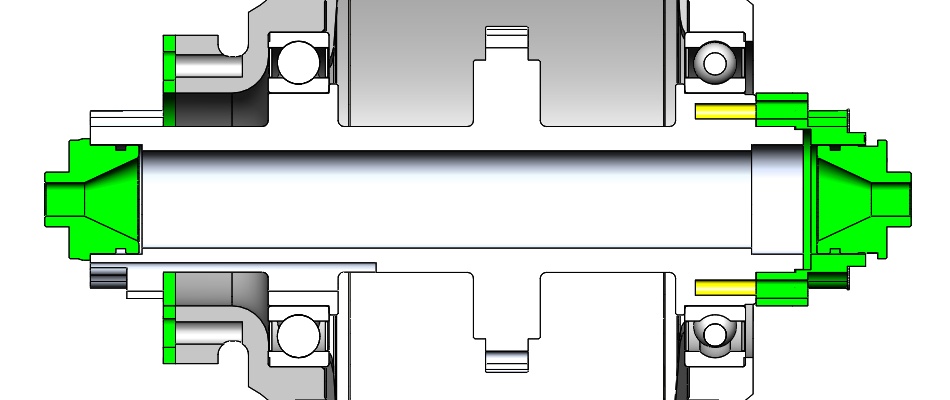

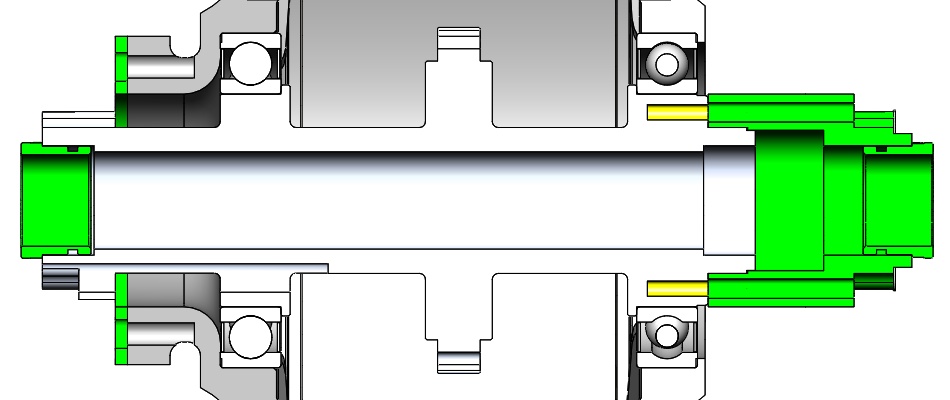

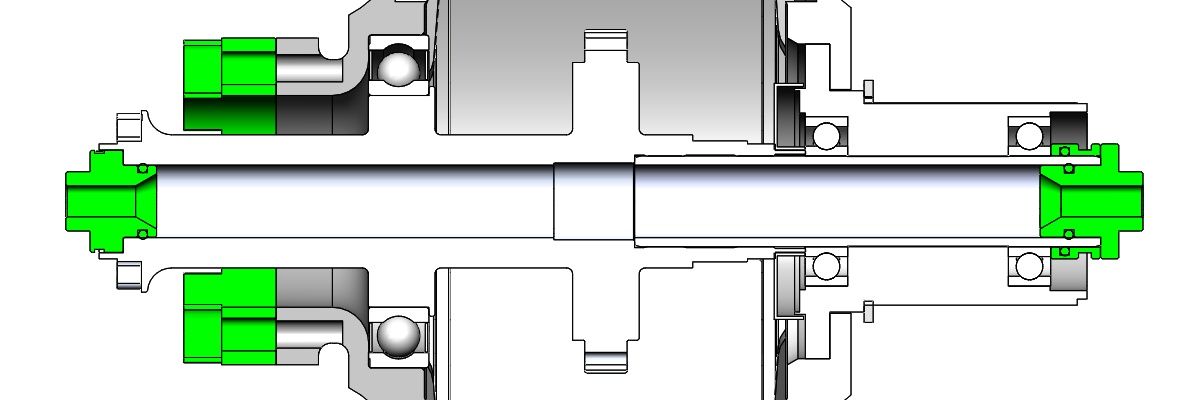

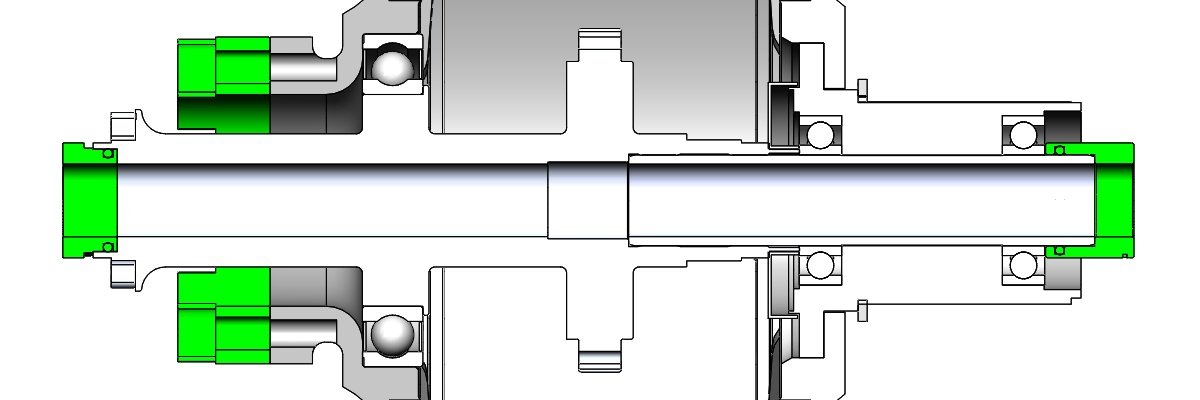

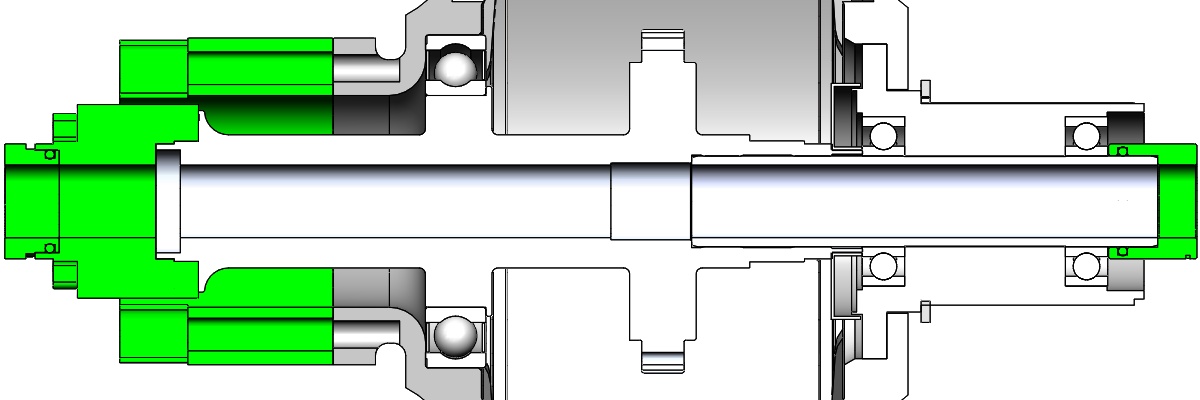

We have made available full 3D models and drawings of the front and rear motors with various adapter sets in order to facilitate vehicle integration.

Videos

Motor Speed

The Original Grin All-Axle Motor is currently produced with three different windings; a slow 8 turn stator, a standard 6 turn stator, and a fast 5 turn stator. Ignoring potential limitations of your motor controller, all three motor winds are capable of producing exactly the same torque and power outputs, so the recommended motor model depends on your desired vehicle speed. The faster wind motors are more appropriate for small wheel diameters and/or lower battery voltages, while the slower motor winds are more common with larger wheel sizes and higher battery voltages.

The following table shows the unloaded speed of each motor winding at common battery voltages in 20" 26", and 29" (700c) wheel sizes.

| Slow 8T Wind (7.5 rpm/V) | Standard 6T Wind (10 rpm/V) | Fast 5T Wind (12 rpm/V) | |||||||

| 20” Wheel | 26” Wheel | 29” Wheel | 20” Wheel | 26” Wheel | 29” Wheel | 20” Wheel | 26” Wheel | 29” Wheel | |

| 36V Battery | 26 kph | 34 kph | 37 kph | 34 kph | 45 kph | 50 kph | 41 kph | 54 kph | 60 kph |

| 48V Battery | 34 kph | 45 kph | 50 kph | 46 kph | 60 kph | 67 kph | 55 kph | 72 kph | 80 kph |

| 52V Battery | 37 kph | 49 kph | 54 kph | 50 kph | 65 kph | 72 kph | 60 kph | 78 kph | 87 kph |

| 72V Battery | 52 kph | 67 kph | 75 kph | 69 kph | 90 kph | 100 kph | 83 kph | 108 kph | 120 kph |

The larger Max45 Motors are available in two winding options*, a slow 5T stator and standard 4T stator. This table shows the unloaded speed of both Max45 motor windings at common battery voltages in 20" 26", and 29" (700c) wheel sizes.

| Slow 5T Wind (7.2 rpm/V) | Standard 4T Wind (9 rpm/V) | |||||

| 20” Wheel | 26” Wheel | 29” Wheel | 20” Wheel | 26” Wheel | 29” Wheel | |

| 36V Battery | 24 kph | 31 kph | 35 kph | 30 kph | 39 kph | 44 kph |

| 48V Battery | 32 kph | 42 kph | 46 kph | 40 kph | 53 kph | 58 kph |

| 52V Battery | 35 kph | 45 kph | 50 kph | 43 kph | 56 kph | 62 kph |

| 72V Battery | 48 kph | 62 kph | 69kph | 60 kph | 78 kph | 87 kph |

*Grin does have 3T stator windings (12 rpm/V) available for special projects.

The top speed under any kind of load is going to be less than this value, and we recommend using our motor simulator for exact performance details of any given combination of motor, battery voltage, and controller model.

Motor Power

The standard All-Axle motor uses a 27mm wide 205mm diameter stator and has similar continuous power and torque capabilities as other direct drive hub motors of this size. However being optimally designed for weight reduction it has less metal mass to absorb heat. Under heavy loads the core temperature will rise at a faster rate than you would see on an otherwise identical but heavier hub, and for those reasons we recommend Statorade in the motor when used in more demanding applications.

The table below shows both the continuous and 5 -minute power capability of the motor at various RPMs with and without Statorde motor coolant. Notice again that the motor winding speed does not impact the power capability of the motor, this table holds true for all three winding options.

| Wheel Speed | Without Statorade | With Statorade | |||

| Continuous | 5 Minute | Continuous | 5 Minute | ||

| 100 RPM | 250 W | 500 W | 340 W | 575 W | |

| 200 RPM | 560 W | 1040 W | 785 W | 1235 W | |

| 300 RPM | 900 W | 1590 W | 1275 W | 1830 W | |

| 400 RPM | 1250 W | 2110 W | 1840 W | 2420 W | |

The fatbike motor with the 45mm stator has a greater power capability. The projected values based on extrapolation from the 27mm motor data are summarized in the table below. This may be subject to change on completion of wind tunnel testing of the fat motor's thermal dissipation characteristics.

| Wheel Speed | Without Statorade | With Statorade | |||

| Continuous | 5 Minute | Continuous | 5 Minute | ||

| 100 RPM | 370 W | 860 W | 840 W | 950 W | |

| 200 RPM | 840 W | 1700 W | 1600 W | 1950 W | |

| 300 RPM | 1330 W | 2600 W | 2500 W | 3000 W | |

| 400 RPM | 2200 W | 3500 W | 3400 W | 4100 W | |

In general, the bottleneck for power and torque capability of these larger motors will be the phase current limit of the Baserunner or Phaserunner motor controller. However, really high current controllers (more than 120 phase amps) are not recommended as both the torque arm and internal mechanics are not designed for the resulting forces. For a more detailed understanding we recommend using our motor simulator or trip simulator applications to properly predict the capability of this motor in any specific usage scenario.

Single Side Applications

A unique feature of the front All-Axle hub design is its ability to work in applications requiring a single side mount. This allows the side wheels of trikes and quads to be readily electrified for the first time, and is especially popular with tadpole trikes running an internal gear hub rear wheel.

A unique feature of the front All-Axle hub design is its ability to work in applications requiring a single side mount. This allows the side wheels of trikes and quads to be readily electrified for the first time, and is especially popular with tadpole trikes running an internal gear hub rear wheel.

Unlike front bicycle forks where there are industry standards (admittedly a lot of standards, but standards at least), the wheel mounting strategy on trikes is all over the map, and unique adapters are required for most vehicle models. We've taken the approach of using the disk caliper mount as an anchor point to hold the wheel and lock the axle against rotation.

|

|

The popular catrikes are ideal for the V2 Grin Hub motor because they already use a 20mm spindle, and they adopt the rear ISO2000 disk caliper mounting standard for both the left and right wheels. |

|

|

The terratrike rovers also have a 20mm spindle, but they use a front ISO disk mount and the shaft has a shoulder that prevents the hub from sliding on as far as would be ideal. We accommodate the terratrike axles with a two-piece torque arm that provides the necessary spacing for where the motor fits in place. |

|

|

This adapter bolts onto a custom machined All Axle Hub Motor to allow for single side mounting to the spindle of certain Icetrike tricycles. The two-piece adapter secures the motor axle to the trike frame via the disk caliper mounting holes. This adapter requires a shim insert to step down the ID of the motor axle to 12mm. |

|

|

The Greenspeed trikes use a smaller 12mm diameter spindle and have a disk caliper location with Rear IS2000 caliper placement. We have a similar 2 piece arm that can be flipped 180 degrees for working on either side. This also requires a shim to step the axle ID down to 12mm. |

HP Velotechnik |

The popular german brand HP Velotechnik makes trikes that all use a 12mm spindle but use a post mount rather than an ISO disc mount. To fit the All-Axle motors on these trikes, we have a disc caliper mounting block that repositions the brake outwards to align with the motor and increases the radial offset for a larger 180mm rotor. The torque arm in this setup is secured to the two fender bolts via a stainless steel plate rather than to the caliper mount. The hardware for the left and right side models are similar, differing only in the direction of bend on the stainless torque arm plate. |

|

|

The splined arm is available by itself for doing DIY mounts on other vehicle types. The two bolt holes allow you to interface with a separate flat plate of metal that can attach under the disk caliper or other frame location on the frame to lock the axle from spinning. |

One Side or Both?

A trike with dual Grin hub motors can be insanely powerful and will be able to rocket up the steepest hills with amazing efficiency, but it is also quite expensive to do a full conversion with two specialized motors and motor controllers. You can also run a tadpole or delta trike with just a single side wheel motor and leave your original wheel on the other side. In general this does not result in any lopsided steering or handling issues and allows for a ligher weight and more economical conversion.

A trike with dual Grin hub motors can be insanely powerful and will be able to rocket up the steepest hills with amazing efficiency, but it is also quite expensive to do a full conversion with two specialized motors and motor controllers. You can also run a tadpole or delta trike with just a single side wheel motor and leave your original wheel on the other side. In general this does not result in any lopsided steering or handling issues and allows for a ligher weight and more economical conversion.

Wheel Lacing

Unlike most hub motors, the All-Axle uses 32 spoke holes rather than 36 spoke holes in order to fit the much larger availability of 32 hole rims. The spoke holes are paired sufficiently close that there is even up to 26" rims there is no need to have the spokes cross over. With a radial lacing the spokes have an effective angle that is the same as a regular hub with a triple cross. That said, you are free to do a single cross lacing if you prefer the look and we recommend single cross for 700c wheels as well.

One not-so-obvious detail is that the spoke flange of the All-axle motor is designed for the spokes to be laced with the elbows in and the head facing outwards. The flange has a couterbore for the spoke head on the outside, and is wide enough apart (49mm, vs 25mm for typical motors) that there is sufficient triangulation with all spokes elbows in. If the wheel is laced with the spoke elbow facing outwards, it results in a bending force on the flange that pushes the entire center of the side plate outwards by 1-2mm. This can result in the motor axle developing play to slide left and right.

Version History

The original V1 All Axle hub motor was in limited production from 2013 until early 2019 and used a large 45mm ID thin section bearing on the side covers and was available in front only. This allowed for a generous amount of room for the heavy gauge phase wires to pass through the axle, but the thin section ball bearings could have short lifespans in setups with frequent exposure to the elements.

In the spring of 2019 we released an updated V2 Grin motor design based on feedback and experience. This updated model has the motor cable exiting on the disc side of the motor rather than the non-disc side to facilitate single side installations, and it uses a wider 35mm ID ball bearing standard with a custom tooled lip seal to prevent ingress and statorade egress. These changes increased the overall motor weight a small amount, but the improved robustness and versatility was worth it.

In January 2024 we updated to a V3 motor design. In the V3 front motors, the ID of the axle was reduced from 20mm to 16mm in order to have more clearance from the disc rotor for the cable exit. And the rear motor was upgraded from a PAS only sensor in the cassette to full torque sensing, the torque arm spline interface was improved, and a wider 45mm fatbike motor variant was added to the mix as well.

| Property | V1 | V2 | V3 |

| Main Bearing | 45x58x7 (6809) | 35x55x10 (6907) | Same as V2 |

| Bearing Seal | Standard Dust Seal | Double Lip Seal | Same as V2 |

| Cable Exit | Non-Disk Side | Disk Side | Same as V2 |

| Axle ID | 20mm | 20mm | 16mm |

| Torque Arm | Non-Disk Side | Non-Disk Side | Same as V2 |

| Connector | Anderson +JST SM | HiGo L1019 | Same as V2 |

| Side Plate Seal | Sillicone Sealant | O-Rings | Same as V2 |

| Statorade Compatibility | So-so (can leak through bearings) | Excellent | Same as V2 |

| Weight | 3.95 kg | 4.05 kg | 4.1 kg |

| Magnets | N35UH | N40SH | Same as V2 |

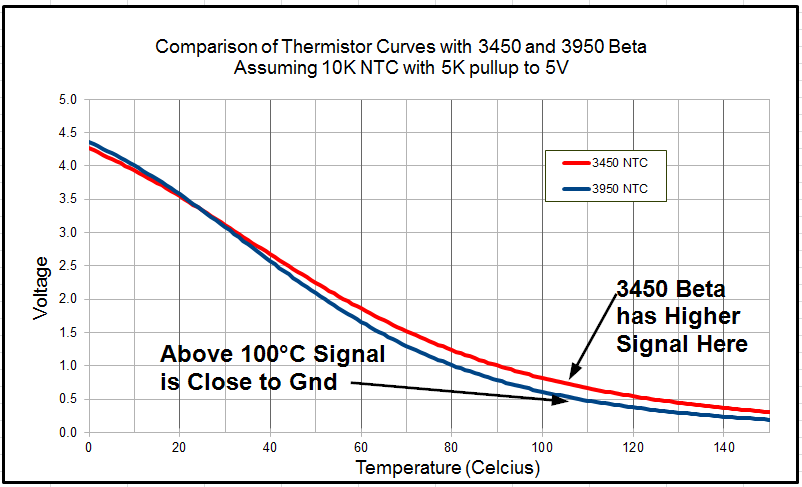

| Thermistor | 10K NTC, Beta 3950 | Originally 10K NTC, Beta 3950 After March 2024, Beta 3450 |

10K NTC, Beta 3450 |

| Property | V2 | V3 |

| Freehub Style | Shimano HG Mountain | Shimano HG Road, or SRAM XD |

| PAS Poles | 12 Pulses / Revolution | 9 Pulses / Revolution |

| Torque Sensing | None | Yes, 28.3 Nm/V |

| Thermsitor | 10K NTC, Beta 3950 | 10K NTC, Beta 3450 |

| Available Adapter Sets | Quick Release: 135x9 Thru-Axle: 142x12, 148x12 |

Quick Release: 135x9, 145x9, 160x9 Thru-Axle: 142x12, 148x12, 157x12, 167x12 |

| Torque Arm | 2 Lobes Only | 2 Lobes plus 4 splines |

In addition to the mechanical changes we also updated from N35 to N40 grade magnets in the move from V1 to V2. Stronger magnets allow the motor to produce more torque for hill climbing with less heat loss, but they also increase the drag of the motor when riding without power. In our original design we erred on having lower rolling drag because at the time we felt this was more important than efficiency on hill climbs, but the Virtual Electronic Freewheeling feature in the Phaserunner/Baserunner controllers has shifted the balance and we switched to a higher strength magnet.

As a result the V2 and V3 motors spin about 5% slower than the V1 models. They have about 10% more drag torque but they can also climb hills with 10% less heat generation.

Motor Colour

We originally launched the V2 front motor in both a shiny silver and black anodized finish, and continue to offer both types. With the introduction of the rear motor having a wide number of variants (3 winding speeds + 3 cassette types), we decided to only list these rear motors in black in order to keep the total SKU count from getting out of hand.

Our original production of side plates used low silicone ADC5 alloy that would anodize to a jet black colour very well. However, due to issues with the injection molding facility we were no longer able to get the plates made with ADC5 after 2023. Since March 2024, all the motor side plates are made with a more conventional die casting alloy that does not anodize quite the same. The result is more of a dark grey colour than a true black.

V3 Model Update Summary

In December 2023 we rolled out significant design update to both the front and rear All-Axle motor models. This was driven by two primary motivations:

1) To resolve the recurring issue of customers experiencing cable damage on front motors due to the small clearance to the spinning disk rotor.

2) To add both torque sensing functionality and SRAM-XD/XDR driver support to the rear motors.

Changes to the Front Design

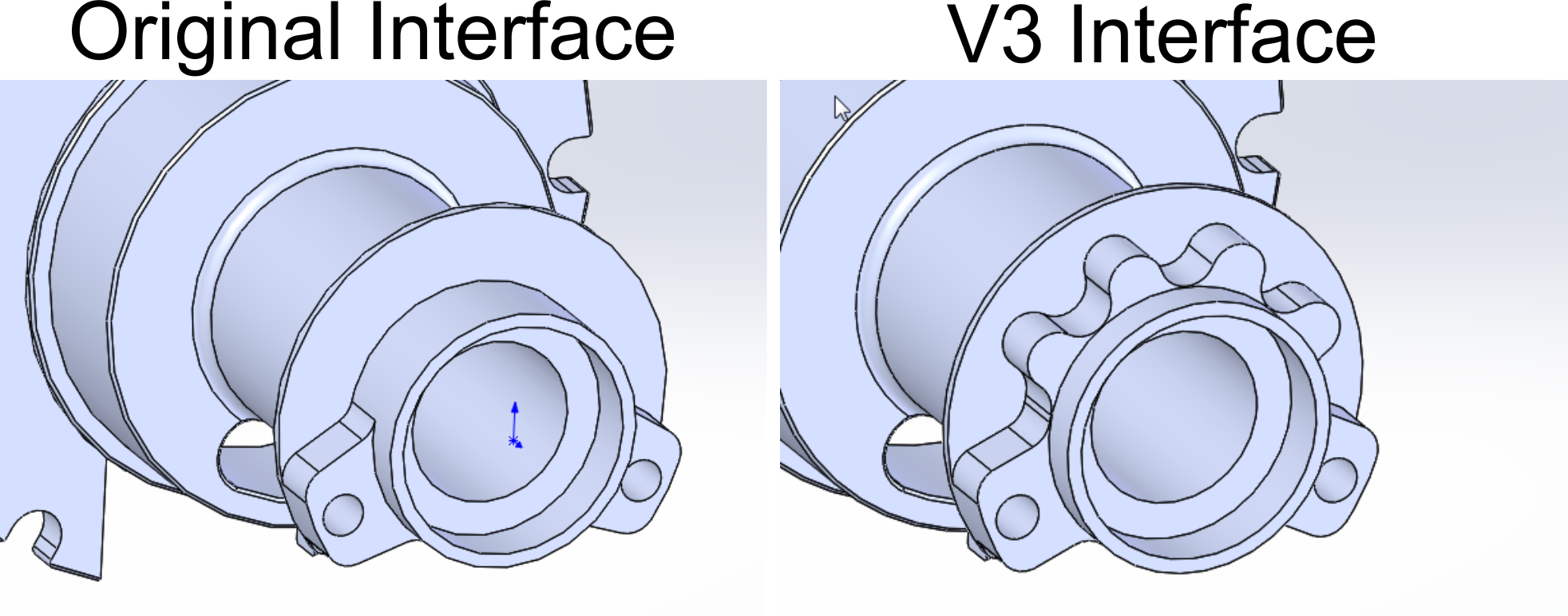

Axle: The front motor now uses an internal 16 mm bore rather than the 20mm bore of the original design. This gives us 2mm more room for the cable to clear the disk rotor. Unfortunately, it also means that the V3 front motor is no longer compatible with 20mm axles. The bicycle industry has long ago moved away from the original 20mm thru-axle fork standard to 12 and 15mm axles instead, so for most this is of almost no consequence. However, we will continue to make the V2 motors available for people who do require compatibility 20mm forks or single-side installations.

Adapters: All of the axle adapters for the V3 motors are different as they must fit into an 18mm recess and not a 20mm ID. We are clearly labeling each adapter set on our store as either a V2 or V3 model to reduce uncertainty, and will always carry a large stock of the V2 adapters to support customers over the years as they move their V2 motor from one bike to another.

Changes to the Rear Design

Freehub: The most significant change is the migration to a new freehub supplier that has options for integrated torque-sensing, rather than our original freehubs that only had basic magnet PAS encoder. There are three options now available

- Shimano HG Torque - This model uses the industry standard Shimano HG freehub body, but using the road rather than mountain standard. By default we are including a 1.5mm spacer to support the more common mountain cassettes, which should be removed if used with a Shimano road cassette.

- SRAM XDR Torque - The option for a SRAM XDR driver gives the ability to use high-end 11, 12, and 13 speed 1x cassettes that have super wide range and a small 10 tooth gear to simplify pedaling at high speeds. Both XD and XDR cassettes are compatible (XD with an included spacer)

- Shimano HG PAS - For those who don't need a torque sensor in their substance, we're planning in 2024 to also offer a less expensive version that has just a basic PAS sensor like our original rear hubs.

These sensors communicate with an internal circuitboard that generate a 0.8V signal at rest, which increases up to 4V as maximum torque is applied. The circuitboard also generates an equivalent 2 wire PAS output to support motor pedal cadence sensing and most importantly back-pedal regen

Torque Arm: The torque arm looks the same externally but internally it now features a set of internal splines in between the two screw holes, providing higher spinout resistance in anticipation of future higher motor models.

Motor Adapters: While the original rear motor had adapters for the three most common dropouts (135mm quick release, 142x12 thru-axle, and 148x12 boost thru axle), the V3 rear motors envision a much wider assortment of adapter sents, including -

- 145x9mm quick release for regular tandem bikes

- 157x12mm superboost thru-axle for mountain bikes

- 160x9mm quick release for Santana Tandem bikes

Disk Spacing:

Finally, the V3 rear all-axle motors are sized so that a 1mm disc spacer is required to correctly position the disc rotor in the bike frame. This increases the caliper clearance to the side plate from 18mm to 19mm which greatly increases the number of brake calipers that will fit without rubbing.

Changes to Both Front/Rear

Thermistor Beta: The 10K NTC thermistor has been changed from one with a 3950 Beta constant to a 3450 Beta constant. This allows for better resolution and accuracy when measuring high motor temperatures, as there is a more discernable voltage change. Most hub motors from other manufacturers that have a thermistor include one with this Beta value, and it is already supported in our Cycle Analysts (V3.15 and later FW) and motor controllers.

45mm Stator for Fabikes: A more powerful motor option using a 45mm stator instead of a 27mm stator was introduced for better fatbike support. This increases the hub flange spacing making it easier to lace into fatbike rims, and it naturally increases the power and weight of the hub too. The front fatbike motor will work with 135x9mm quick release and 150x15 thru-axles, while the rear fatbike version will support 170/177 dropouts for 4" tires, and 190/197 dropouts for 5" tires.

Background

The All-Axle motor has been a long development project for Grin to produce a direct drive hub motor that was lightweight and compatible with all Thru Axle and quick release fork standards. The idea first took roots in 2010 when we were impressed with the performance of large diameter direct drive hub motors being imported from china, but increasingly frustrated with the poor mechanical tolerances and bike fitment. While prototyping these mechanical improvements we also saw considerable opportunity to reduce the mass of the hub without affecting the torque output.

These earlier videos filmed from Ken (owner of a Calgary based ebike store) as he was passing through town in 2010 show the early development and thought process:

Since then we've gone through a number of design revisions, enhancements, mold toolings, and several pilot production batches while working out many kinks along the way. The hub was really put to the test in several touring trips (such as 2013 cargo biking Vancouver to San Francisco, and the 2018 Sun Trip solar bike race) and has finally come of age in 2019 with the V2 model when we switched to a wider and more rugged bearing, cable exit on the disk side, and a move to o-ring seals rather than silicone sealant for the side plates and screws for more consistent mass production and easier servicing.

Marine Motor - PAUSED

UPDATE: The Marine Motor development was paused in 2022 as Grin needed to focus on updates to our core ebike kit offerings and manufacturing capabilities. We hope to resume this project in full capacity in 2024 and will email everyone who has expressed interest once we re-embark on this project. The marine motor axle design has been fully re-engineered to be stackable so that 2 or 3 motors can be added end to end.

We are actively developing a Marine version of our All Axle motor for people interested in electric sailboats conversions. The ~4kg motor can directly replace a much more massive diesel engine, and it is perfectly matched to drive the shaft 1:1 with no transmission required. Our standard width Grin motor with a 27mm wide stator can effectively replace an 8 horsepower engine, while a fatter 45mm stator option could replace a 12 hp diesel. This should broadly cover most sailboats with the 24-32 foot realm, or larger vessels if you don't mind being under powered.

We are planning to do a pilot launch of this motor in summer 2021 and are currently looking for potential pilot customers in BC lower mainland or Vancouver Island. Ideally these are people who have an existing sailboat with an inboard engine that is due for replacement, and with the drive shaft still in place. If that situation rings a bell and you have a strong interest in going electric, please fill out the google form below:

Intro to Shamrock, Justin's first electric sailboat conversion

Please read this forum thread for more detailed information and updates!

https://endless-sphere.com/forums/viewtopic.php?f=39&t=108411

Part2: https://www.youtube.com/watch?v=4kAsdIiD8d4

Part3: https://www.youtube.com/watch?v=PBBeLVNga2s

Part4: https://www.youtube.com/watch?v=KTruEiFRNGM

Part5: https://www.youtube.com/watch?v=ZeEs-F0RZAs

Part6: https://www.youtube.com/watch?v=RT5OxJd1F8g (The End!)

This summer Justin completed what had been a long sought dream replace the inboard diesel engine of his 25 foot sailboat with a pure electric drive. After crunching some numbers and looking at the mechanical clearances, he realized that he could pull this off using a direct drive electric bicycle hub motor attached to the prop shaft with no transmission at all.

This video shows an overview of the motor installation and captures the very first sea trial as we powered the boat over to the dry docks for a needed cleaning and overhaul.

Shamrock Electric Sailboat Conversion Part 2 - Sea Trials with 72V Lithium Battery Bank

Part1: https://www.youtube.com/watch?v=JuIG5Uqk4_c

Part2: -- This Video You are Watching --

Part3: https://www.youtube.com/watch?v=PBBeLVNga2s

Part4: https://www.youtube.com/watch?v=KTruEiFRNGM

Part5: https://www.youtube.com/watch?v=ZeEs-F0RZAs

Part6: https://www.youtube.com/watch?v=RT5OxJd1F8g (The End!)

This 2nd video was filmed in the early fall of 2020 after Shamrock got a complete overhaul on the dry docks and had a large 72V battery bank installed. We went for an afternoon sail to show the power vs speed relationship and demonstrate regenerative energy capture from the propeller under sail.

Unfortunately the instrumented motor mount had to be temporarily scrapped since it wasn't rigid enough and allowed the motor and shaft to wobble, but we were still able to get some precise and useful data right up to 3000 watts just with the Cycle Analyst.

For our next project we will be replacing the Phaserunner with a larger and much more powerful BAC8000 controller from ASI in order to run the grin motor right up 5000 watts. Stay tuned to see the maximum and continuous powers we can get from a simple hub motor in this application!

Please read this forum thread for more detailed information and updates

https://endless-sphere.com/forums/viewtopic.php?f=39&t=108411

Shamrock Electric Sailboat Conversion Part 3 - BAC2000 Controller Upgrade for 5kW

Part1: https://www.youtube.com/watch?v=JuIG5Uqk4_c

Part2: https://www.youtube.com/watch?v=4kAsdIiD8d4

Part3: WHAT YOU ARE WATCHING

Part4: https://www.youtube.com/watch?v=KTruEiFRNGM

Part5: https://www.youtube.com/watch?v=ZeEs-F0RZAs

Part6: https://www.youtube.com/watch?v=RT5OxJd1F8g (The End!)

This 3rd video is from Spring 2021 after we upgraded the controller from the small Phaserunner to the ASI BAC2000 device, allowing us to run at the full 5kW power levels and characterize the energy consumption curve right up to hull speed (6 knots, 11 kph).

Our next focus after this will be a first-order solar installation to keep the batteries charging automatically on longer summer trips, so stay tuned for constant updates.

Please read this forum thread for more detailed information and background

https://endless-sphere.com/forums/viewtopic.php?f=39&t=108411

Shamrock Electric Sailboat Conversion Part 4 - Installing a Massive Solar Array

Part1: https://www.youtube.com/watch?v=JuIG5Uqk4_c

Part2: https://www.youtube.com/watch?v=4kAsdIiD8d4

Part3: https://www.youtube.com/watch?v=PBBeLVNga2s

Part4: WHAT YOU ARE WATCHING

Part5: https://www.youtube.com/watch?v=ZeEs-F0RZAs

Part6: https://www.youtube.com/watch?v=RT5OxJd1F8g (The End!)

This 4th video goes over the design, assembly, and installation of a large solar array that will let us charge the 72V lithium battery pack both while underway and at anchor. All told we put 1300 watts of Sunpower flexible solar panels around the boat, 400 on each side and 500 on the back. The side panels can fold up and down both to aim at the sun or be out of the way, while the rear panel can angle forwards and back as well.

It's a lot more solar than you normally see on a sailboat, but when all your propulsion is electric and our plan is summer coastal cruising in frequently low winds, then every watt is worth it to harvest!

We used a mixture of 3D printed fittings and aluminum tubing to make the panel support structure and attachment anchors to the boat, and it all came together in about 1 week's time before a planned mid-August sail trip.

Please read this forum thread for more detailed technical information on this project:

https://endless-sphere.com/forums/viewtopic.php?f=39&t=108411#p1585329

Shamrock Electric Sailboat Conversion Part 5 - Maiden Trip under Solar, Across the Georgia Straight

Part1: https://www.youtube.com/watch?v=JuIG5Uqk4_c

Part2: https://www.youtube.com/watch?v=4kAsdIiD8d4

Part3: https://www.youtube.com/watch?v=PBBeLVNga2s

Part4: https://www.youtube.com/watch?v=KTruEiFRNGM

Part5: -- This Video --

Part6: https://www.youtube.com/watch?v=RT5OxJd1F8g (The End!)

The 5th installment of our electric sailboat video series captures our first trip with the 1300 watt solar array, a 90km (50 nautical mile) crossing of the Georgia Straight from North Vancouver to Sidney, BC. We were busy rebuilding the side panel attachments the night before, and barely got a moment of sleep let alone a chance to test run the setup before heading out.

Luckily it turned out to be a gorgeous day!

Please read this forum thread for more detailed technical information on this project:

https://endless-sphere.com/forums/viewtopic.php?f=39&t=108411#p1585329

Intro to Belle Amie, 32 foot Electric Sailboat Conversion, Part1

Toni from Victoria reached out to us after seeing our conversion series about Shamrock, the 25 foot sailboat that we electrified with an adapted ebike hub motor. (https://www.youtube.com/watch?v=JuIG5Uqk4_c&list=PLH8T1SX8ZJv-cP7opmQiJs0DYDIGi5Ps7)

She has a 32 foot live-aboard sailboat and has long dreamed of shedding the troublesome diesel engine in favor of an all electric drive. Meanwhile, we were looking for a platform to field test the higher power version of this motor in a larger vessel than Shamrock, and thus the stars aligned for our second foray into an eboat conversion!

This is the first part of a series that will document our experiences with electrifying Belle Amie. We hope you enjoy what it with lots more to come as the spring and summer unfold.

UPDATE:

Part 2 is here: https://www.youtube.com/watch?v=B8Uh4onqTAU

Part 3 is here: https://www.youtube.com/watch?v=GbVXhBRx-Oo

Belle Amie Part 2, New Propeller, Solar Panels, 20kWhr Battery on 32 Foot Electric Sailboat

This is a 5 month follow up on Grin's 2nd electric sailboat conversion, the 32 foot Belle Ami we introduced here:

https://www.youtube.com/watch?v=oPMxY4LinKA

We installed one of the larger Grin motor drives with a 48V battery bank and since then she's done many long and short boating trips without even a hiccup. But it was topping out at around 4 knots, a result of poor propeller pitch for this particular motor and several years of marine growth on the hull. And at full power there was a lot of vibration that was a bit disconcerting.

So once Toni mentioned that she had the boat on an improvised tidal lift to repaint the bottom, we took that opportunity to come visit and install a more suitable 3 blade propeller.

This video shows that process and gives an overview of the battery bank and solar array that have also been installed.

In our next Part3 video we promise some actual sailing footage! and data collection!

UPDATE: Part3 is here: https://www.youtube.com/watch?v=GbVXhBRx-Oo

Belle Amie Part 3, Cruising experience to Vancouver, Speed Trials, and a Northbound sendoff

In this installment of the Belle Ami electric sailboat conversion, Aaron tagged along with Toni and her friend Maria as they left Sidney to start heading North for the summer. They met up with Justin and the Shamrock sailboat in Vancouver for the fireworks, did a bunch of repairs, and then ran speed / power trials to better characterize the system while heading up to the Sunshine Coast.

The whole footage was nearly lost when the camera carrying our memory card was knocked overboard just before the fireworks show. But luckily Diver Dan came to our rescue and was able to salvage it from the deep. So thank you Dan!

0:00 - Intro

1:35 - Sea Tales of Maeve

2:32 - Gulf Islands Passage

4:40 - Crossing the Straight of Georgia

7:06 - English Bay and Fireworks

8:23 - Data Logging

11:55 - Trip Experience

14:27 - Camera Dive

Here are the two previous episodes covering this conversion:

Part 1: https://www.youtube.com/watch?v=B8Uh4onqTAU

Part 2: https://www.youtube.com/watch?v=oPMxY4LinKA

Shamrock Part 6 - The End! Final Episode of Electric Sailboat Project. Reflections and What's Next

This 6th video covers the last 3 years of using Shamrock until she was unexpectedly ripped from a mooring buoy and sunk just a week before we were going to move into a winter slip. It's not at all the ending that we expected. But we certainly got a lot out of this old Cal25 in the 8 years that we had her, the last 5 under electric propulsion. This video is a chance to provide a full recap on those experiences and discuss what's next.

Previously:

Part1: https://www.youtube.com/watch?v=JuIG5Uqk4_c

Part2: https://www.youtube.com/watch?v=4kAsdIiD8d4

Part3: https://www.youtube.com/watch?v=PBBeLVNga2s

Part4: https://www.youtube.com/watch?v=KTruEiFRNGM

Part5: https://www.youtube.com/watch?v=ZeEs-F0RZAs

Sections:

0:00 - Intro to 30' Ariel

2:14 - No More Marina

3:12 - Tragedy

6:59 - Refloating

9:58 - Submerged Parts Survival

13:18 - Background Story to Shamrock

15:23 - Positive Experience Recap

17:41 - Limitations

22:52 - Solar Thoughts

24:40 - Battery Thoughts

25:35 - Regen Thoughts

27:03 - The Bayfield 32

30:50 - Stacked Motors

Where to Order

The Grin All Axle hub motors are available in stock at our shop in Vancouver and our distribution partner Grintech.eu in France, and also sold through dealers all over the world, including ebike-solutions in Germany, BikeToTheFuture in Switzerland, and BikeSwift in the USA

Canadian

Canadian

Catrike

Catrike Terratrike

Terratrike Icetrike

Icetrike Greenspeed

Greenspeed DIY

DIY Full All-Axle Conversion Kits from our Online Store

Full All-Axle Conversion Kits from our Online Store