Draft

Dealer and OEM Inquiries

Grin’s All-Axle hub motor is ideal for both ebike fabrication businesses wanting a versatile drive system as well as bicycle stores looking to offer quality electric conversion services. Over 50% of our motor sales are B2B and we want to get this great motor into even more hands!

We at Grin are avid cycling enthusiasts/bike mechanics ourselves and are acutely aware of the limitations of imported hub motor kits. Our goal was to offer a system that would eliminate all the common installation/compatibility headaches of such kits.

The All-Axle Advantage - Bicycle/Ebike Stores

Are you running one of those gems-of-a-store retrofitting all kinds of bikes into ebikes? Then our All-Axle Motor is right for you! This family of motors covers all the bases for you:

Light (and lighter!)

than comparable to BBSHD/Tongshen mid-drive kits.

Installs on (almost) Every Frame and Fork

Installs on (almost) Every Frame and Fork

With adapters to fit all major standards. We even have single-sided axle adapters for trikes! And talk to us if you have one that won't!

Integrated Torque Arm with Single Point Release

Means no destroyed dropouts, even on front suspension forks and carbon fiber frames.With quick release wheels, a single M5 bolt releases the whole wheel easily for service.

Integrated Torque Sensing Freehubs = no bottom bracket torque sensors

Rear AA Motors have built-in freehub torque sensors - bottom bracket torque sensors not needed!

Simple Regen Control

Twist the throttle forwards for power, backwards for electronic braking. No additional sensors or special brake levers to activate regen.

One Family of Motors, All-Axles, All Builds

Commonality means less time learning and more time building. Build almost any kind of ebike or etrike that easily outperforms most integrated factory equivalents, offering upgrades that most shops simply cannot.

Rapid Installation Ready

<Recent 4 minute video of all-axle install>

Our kits with prelaced motors and Baserunner-equipped downtube batteries can typically be installed in less than an hour.

CUSMA Trade Compliant

CUSMA Trade Compliant

Made in Canada, ready for tariff free shipping to the US, unlike the hassles and trade uncertainties when ordering from China.

EU Compliant(ish)

Dealers in Europe can order directly from grintech.eu located in France with all VAT prepaid. The motor is RoHS compliant and is being tested as part of complete ebike builds certified to EN19154

The All-Axle Advantage - OEMs

There’s a whole new class of ebikes/light electric vehicles that Grin’s All-Axle Motor is perfect for. Many of our OEM clients are using our motors to build powered velomobiles, handcycles, adaptive trikes, cargo haulers, best-in-class premium ebikes and even multi-motor drive vehicles.

[pics of innovations]

If yours is such a setup, we would love to supply you with our All-Axle Motors.We are especially great for OEM’s who:

Are Doing Assembly in the West

not Asia, and marketed as having domestically-made components

Need Small Batch Production Runs

from a few dozens to about 200+ pcs (more negotiable, of course!)

Need a Highly Adaptable Motor

With optional torque/PAS integration. We cater to almost all installation scenarios (including single sided axles), with adapters to fit almost every standard.

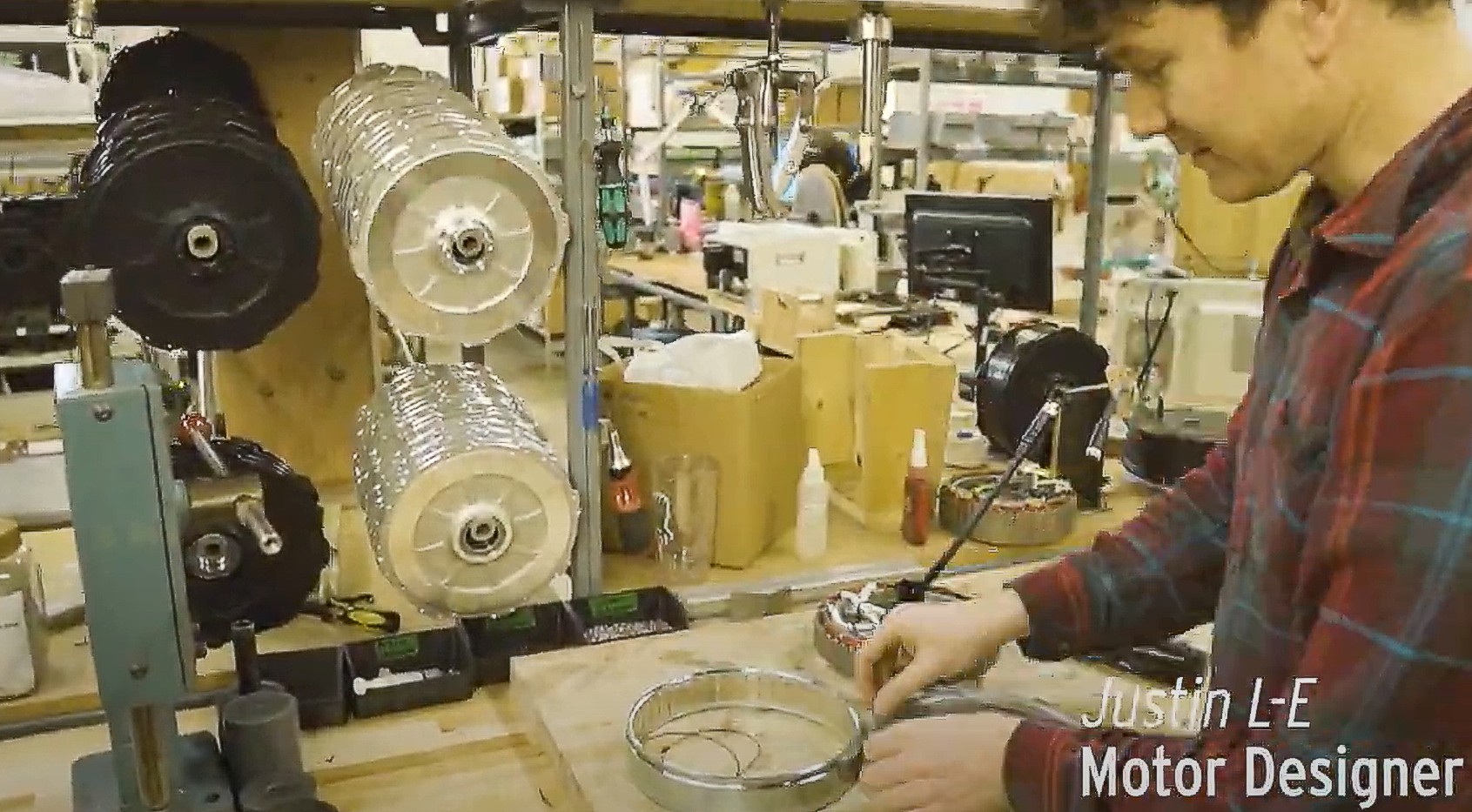

Want to Work Directly with the Tech Folks

who are intimately involved with the design of the All-Axle and having deep understanding of motor performance and vehicle integration.

Contacting Grin

So if you are considering using the All-Axle Motor for your business and would like to know about our wholesale rates, please email us with details of your application and questions you may have. Our technical/sales staff will guide you through the next steps and schedule a video/phone call as needed.

Advance note: Grin does not offer credit terms to businesses. All orders, regardless of volume, need to be fully paid before we ship them out. We’re great engineers and fabricators, but not so good as bankers :) !

Canadian

Canadian